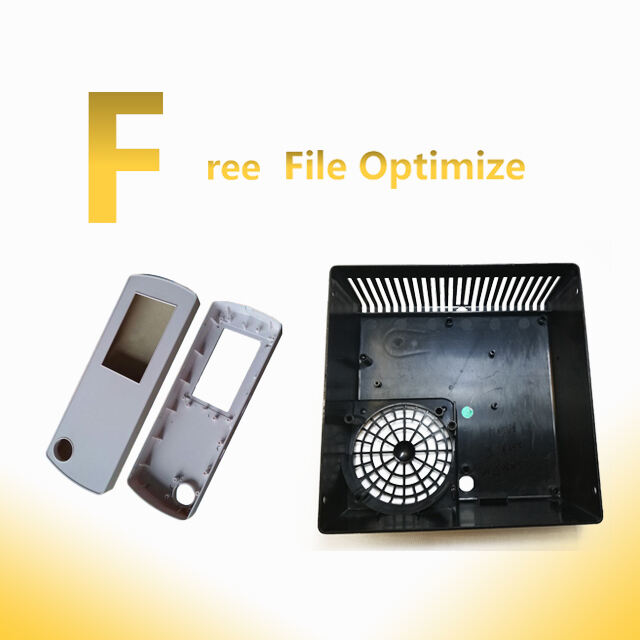

custom molded plastic parts

Custom molded plastic parts are precision-engineered components designed to meet specific application requirements. These parts are made through a sophisticated molding process that shapes plastic materials into intricate and precise forms. Main functions include structural support, component housing, and protective casings. Technological features such as high-precision molds, a variety of material options, and advanced thermal management systems are integral to their design. These features ensure that the parts are durable, lightweight, and can withstand harsh environmental conditions. Applications span across various industries, including automotive, aerospace, medical devices, consumer electronics, and more, where reliability and efficiency are paramount.