injection molding cost per part

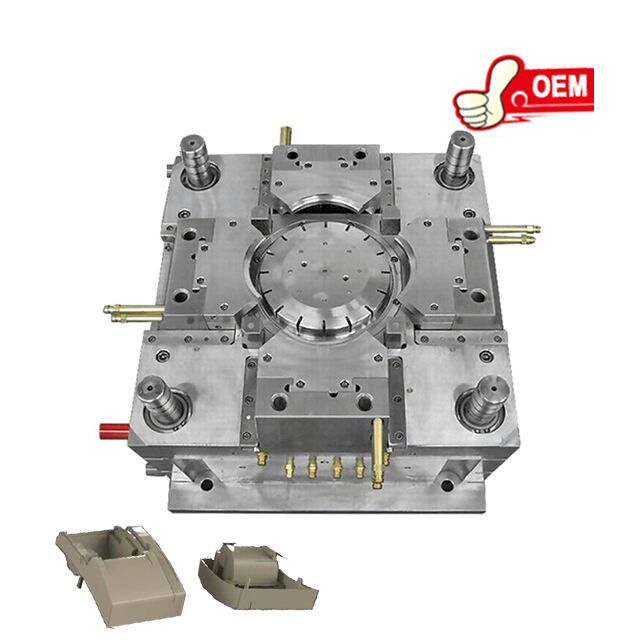

Understanding the injection molding cost per part involves recognizing its primary functions, technological features, and diverse applications. Injection molding is a manufacturing process where molten material is injected into a mold to produce parts in large volumes. The cost per part is determined by factors like the complexity of the design, the material used, and the efficiency of the production process. Main functions include producing high precision parts with intricate details quickly and consistently. Technological features include the use of advanced machinery and automation, which ensures high production rates and minimal waste. This process finds applications across industries such as automotive, medical, electronics, and consumer goods, making it an indispensable part of modern manufacturing.