plastic injection molding industry

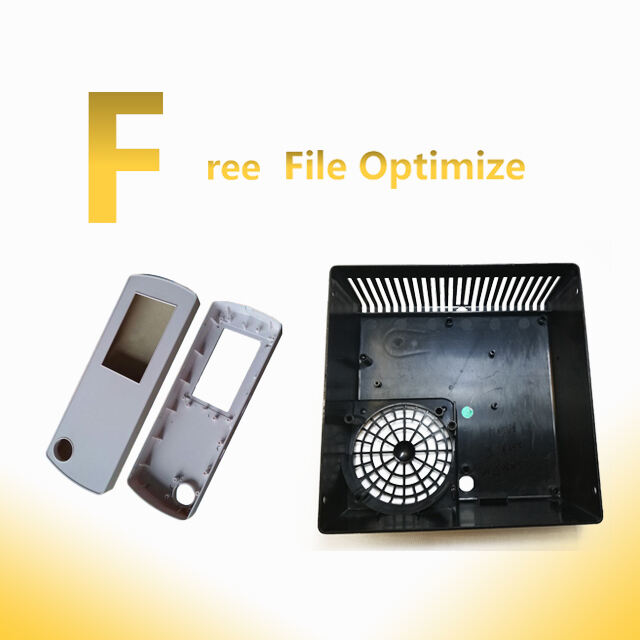

The plastic injection molding industry is a cornerstone of modern manufacturing, responsible for producing a vast array of plastic products used in everyday life. The main functions of this industry involve melting plastic pellets, injecting them into a mold under high pressure, and then cooling the mold to solidify the plastic into the desired shape. Technological features include precision molds, advanced control systems, and automated processes that ensure high consistency and quality of the final products. Applications span across various sectors such as automotive, medical, consumer goods, and electronics, where intricate and durable plastic components are essential.