plastic moulding business

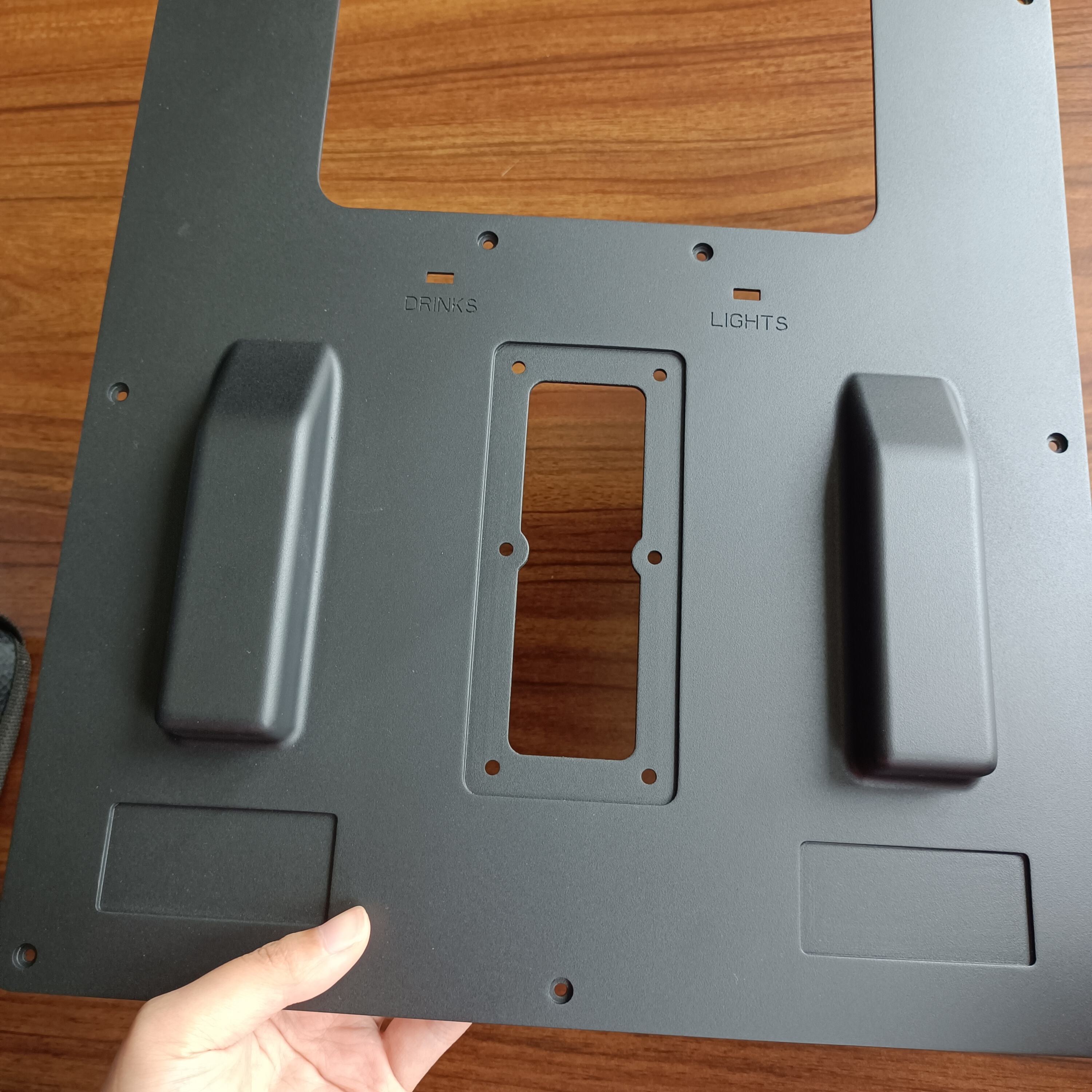

The plastic moulding business is a cornerstone of modern manufacturing, specializing in the production of plastic parts and components through a sophisticated process. At its core, plastic moulding involves heating plastic material until it melts and then injecting it into a mould cavity, where it cools and solidifies into the desired shape. The main functions include design, mould fabrication, material selection, and the moulding process itself. Technological features of this industry include advanced moulding machines, robotic automation, and precision engineering, which ensure high-quality and consistency in production. Plastic moulding finds applications across various industries such as automotive, healthcare, electronics, packaging, and consumer goods, demonstrating its versatility and importance in the global market.