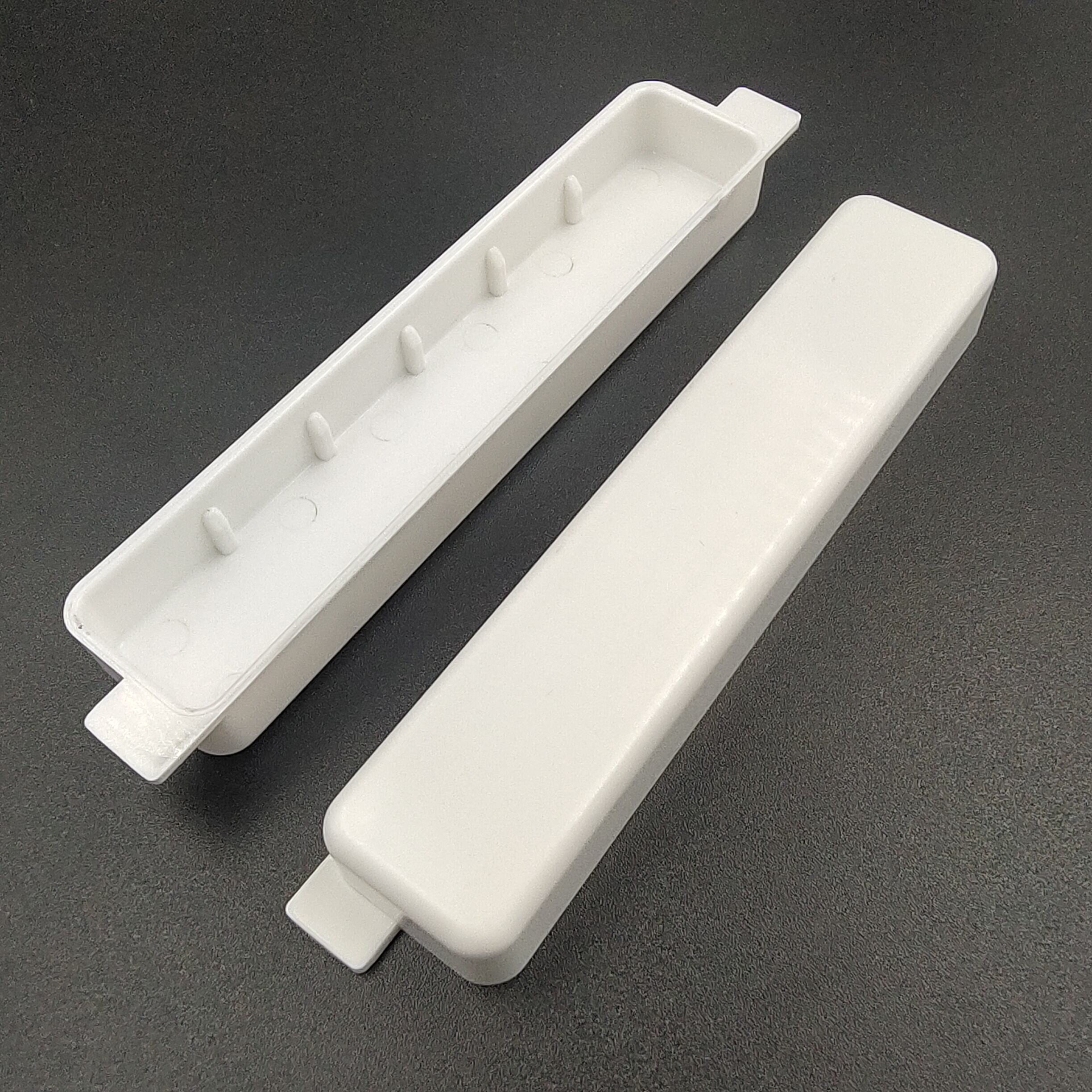

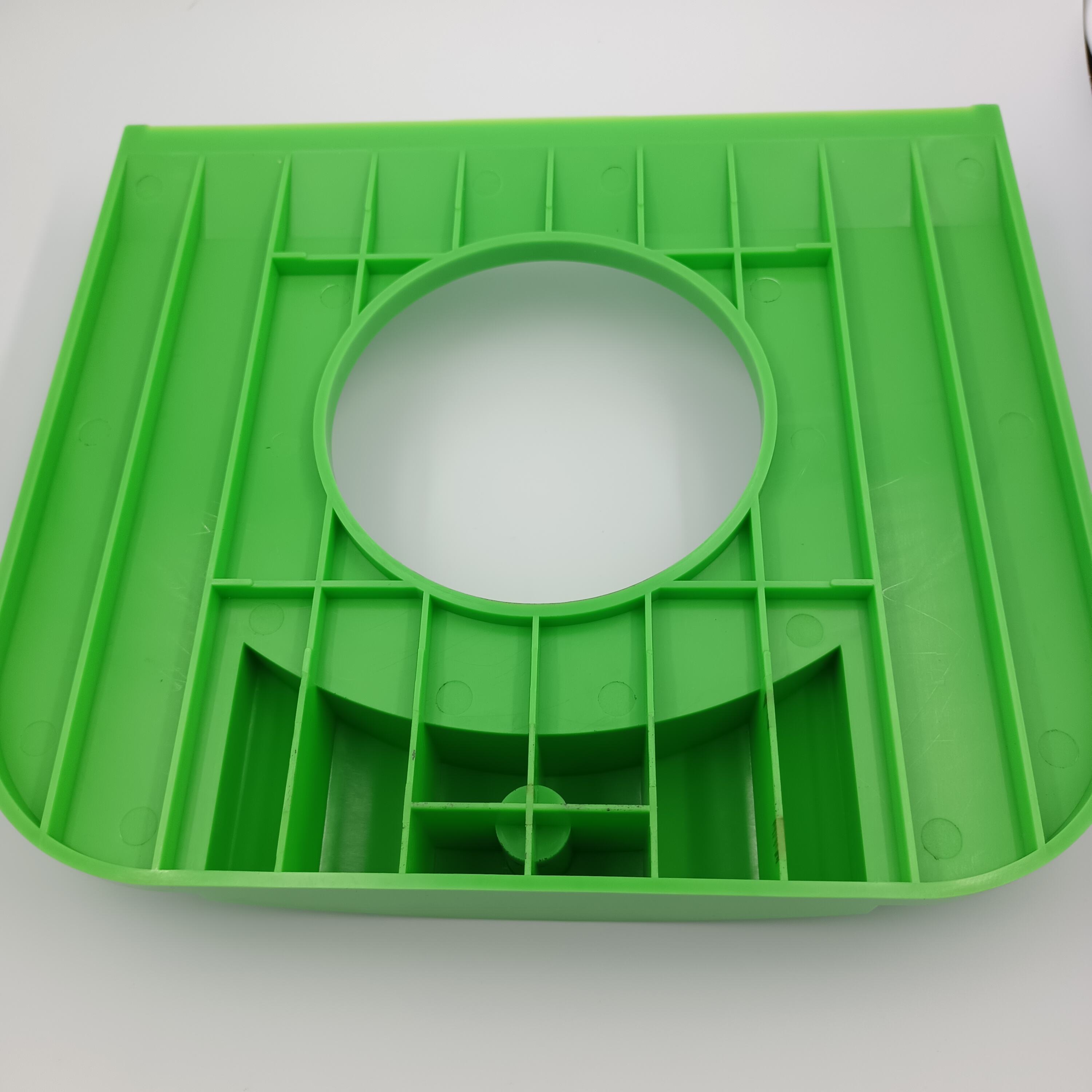

cheap plastic injection molding

Cheap plastic injection molding is a cost-effective manufacturing process used to produce parts by injecting molten plastic into a mold cavity. Its main functions include shaping, forming, and producing intricate plastic components quickly and efficiently. Technological features of this process encompass high precision, the ability to create complex shapes, and consistency in production. The applications of cheap plastic injection molding are widespread, ranging from automotive parts and medical devices to consumer goods and electronic components. This process is integral to various industries due to its versatility and the capability to produce large volumes of parts with tight tolerances.