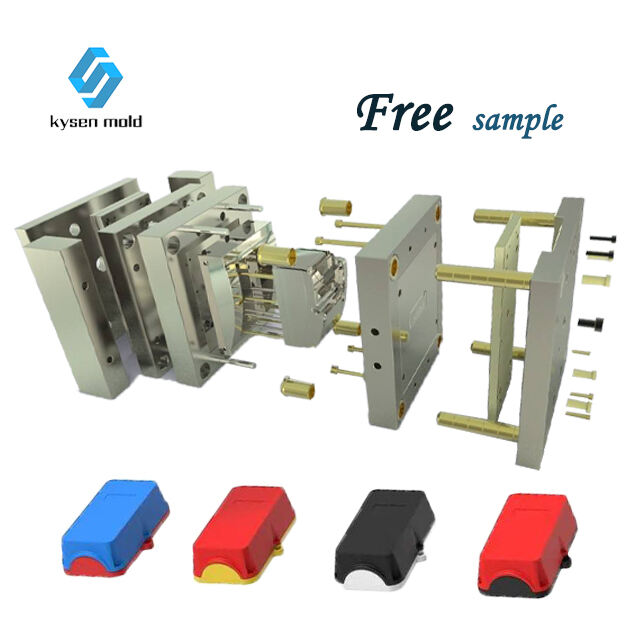

small scale plastic injection molding

Small scale plastic injection molding is a precision manufacturing process used to produce small to medium-sized plastic parts with high accuracy and repeatability. Its main functions include injecting molten plastic into a mold cavity, cooling it, and then removing the solidified part. Technological features of this process include the use of specialized injection molding machines that can handle small batches with efficiency and precision. The machines are equipped with advanced control systems that ensure consistent quality in every part produced. Applications of small scale plastic injection molding are diverse, ranging from medical devices and electronics to automotive components and consumer goods. The ability to produce complex shapes and tight tolerances makes it ideal for industries that require high-quality, intricately designed parts in smaller volumes.