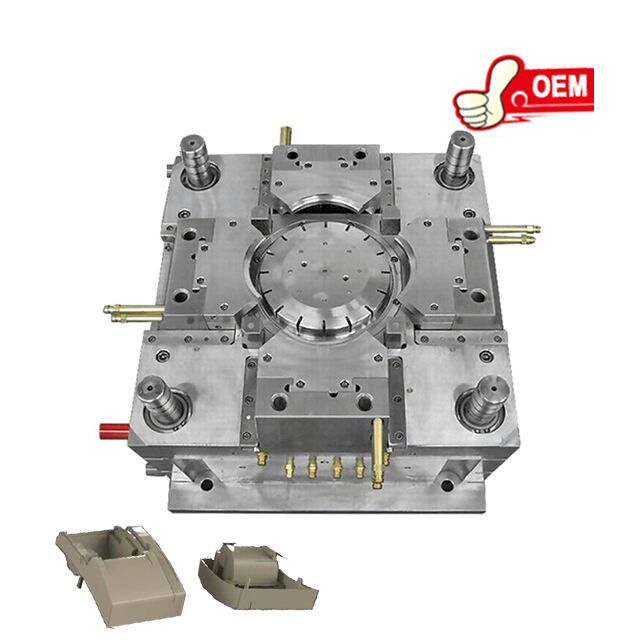

family mold injection molding

Family mold injection molding is a sophisticated technique used in plastic manufacturing, characterized by its capability to produce multiple parts through a single mold. The primary function of family molds is to increase efficiency by reducing the number of molds needed for production. Technological features include advanced design software for mold creation, precision engineering for intricate part designs, and automated systems for high-volume production. This method is highly versatile, with applications spanning across various industries such as automotive, electronics, and healthcare, where complex components are required in large quantities.