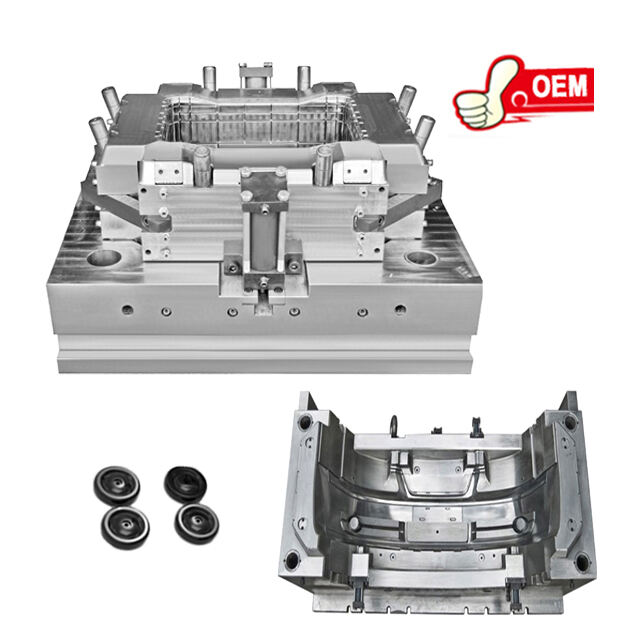

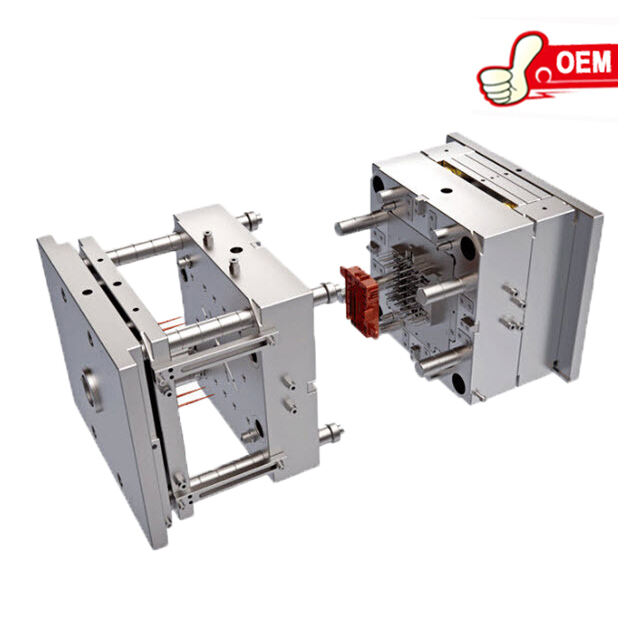

high precision injection molding

High precision injection molding is a sophisticated manufacturing process that involves injecting molten material into a mold cavity to produce parts with exceptional accuracy and intricate details. Its main functions include producing complex shapes, maintaining tight dimensional tolerances, and ensuring consistent quality in high-volume production. Technological features of high precision injection molding include advanced mold designs, precise temperature control systems, and state-of-the-art injection machines that guarantee superior surface finish and dimensional stability. This process finds extensive applications in industries such as automotive, medical, aerospace, and electronics, where precision and quality are of paramount importance.