injection molding cost per unit

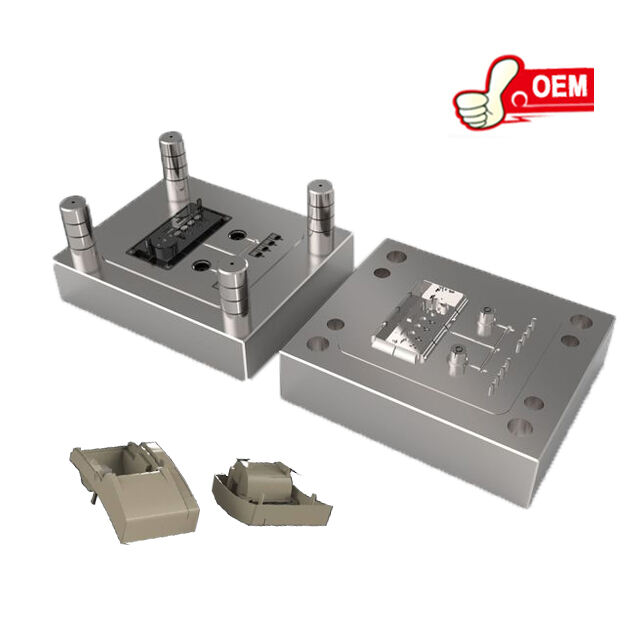

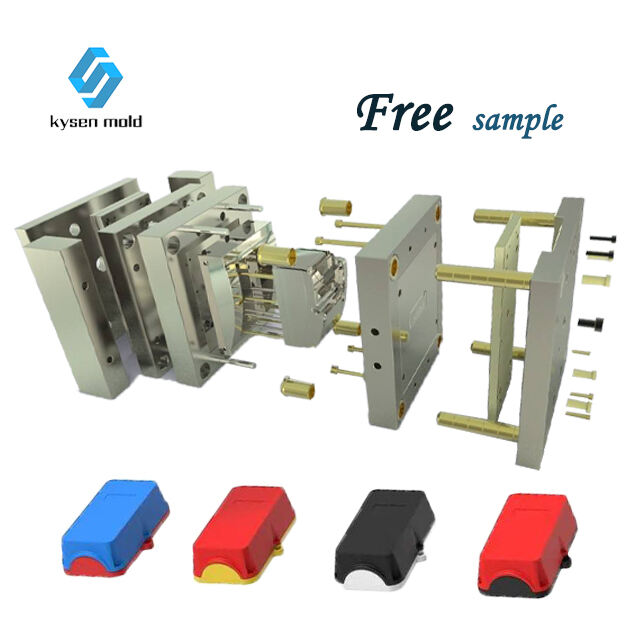

The injection molding cost per unit is a critical factor for manufacturers looking to produce plastic parts efficiently and at scale. This cost encompasses the expenses related to machinery, labor, materials, and overhead. The main functions of injection molding machines include heating the plastic material, injecting it into a mold, cooling it, and then ejecting the final product. Technological features such as precision molds, automated systems, and advanced control software ensure high-quality production with minimal waste. Applications of injection molding are widespread, from automotive parts to consumer electronics, medical devices, and more, making it a versatile solution for various industries.