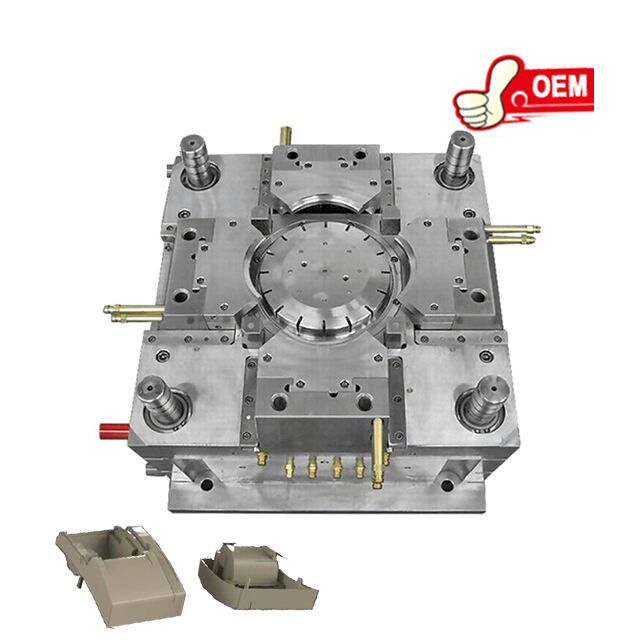

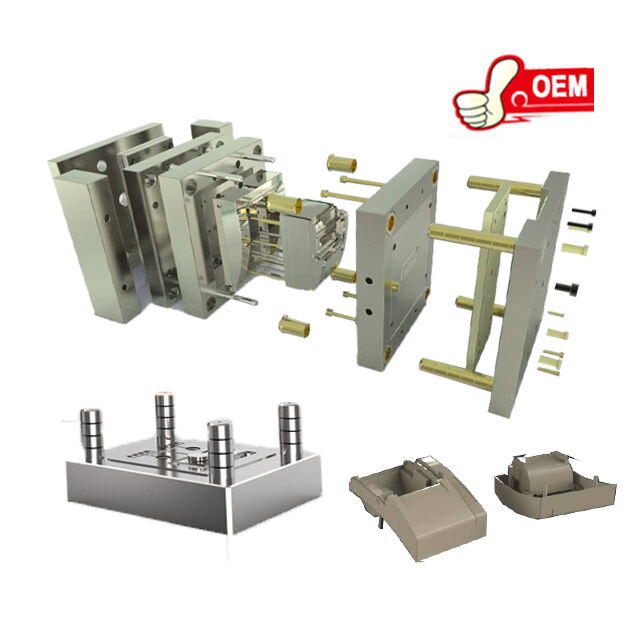

dual shot injection molding

Dual shot injection molding is an innovative process in the plastic manufacturing industry that involves the simultaneous use of two injection units to mold a part in a single operation. The main functions of this technology include producing high-quality, complex parts with two different materials or colors in one cycle. Technological features of dual shot injection molding include precise control over the injection of materials, reduced production time, and the ability to create parts with enhanced mechanical properties. This process finds extensive applications in the automotive, medical, and consumer goods industries, where the demand for high-performance, multi-material components is rising. Dual shot injection molding enables manufacturers to integrate multiple functions into a single part, thereby reducing assembly costs and improving product performance.