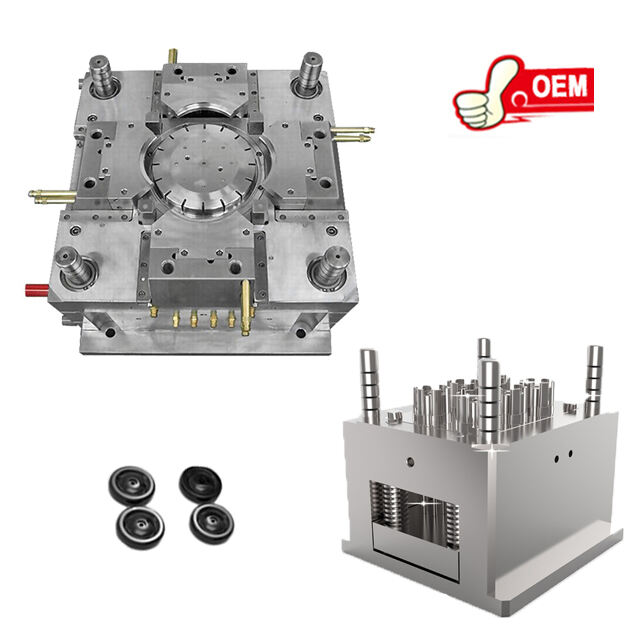

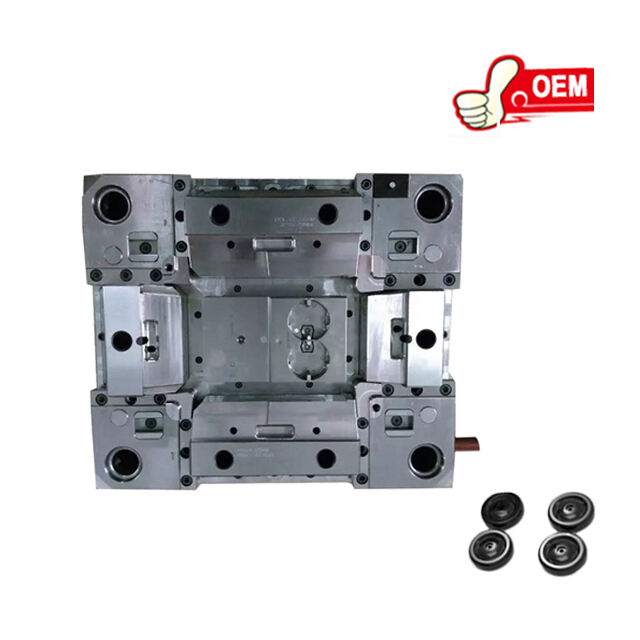

injection molding plant

At the heart of modern manufacturing lies the injection molding plant, a facility dedicated to precision plastic production. This state-of-the-art plant performs a variety of essential functions such as material handling, injection molding, and quality control. Advanced technological features like automated robotics, precise temperature control systems, and high-speed injection units enable the creation of intricate parts with high consistency and reliability. The applications of the injection molding plant span across industries, from automotive and electronics to healthcare and consumer goods, making it an indispensable component in the production of a myriad of everyday products.