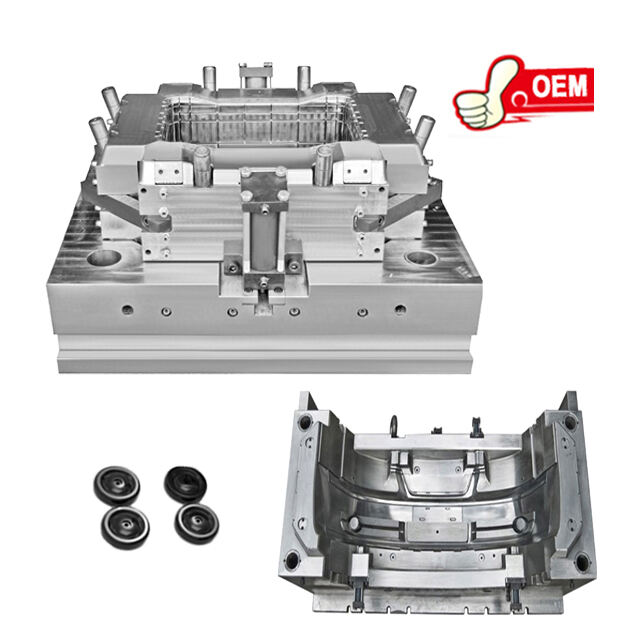

soft tooling injection molding

Soft tooling injection molding is an innovative process in the plastics manufacturing industry that utilizes temporary molds, typically made from materials like aluminum or silicone, to produce plastic parts. The main functions of soft tooling injection molding include rapid prototyping and low-volume production, providing a cost-effective solution before investing in traditional, expensive steel molds. Technological features of this process involve the use of advanced CAD/CAM software for precise mold design and the capability for quick mold fabrication. The applications of soft tooling injection molding are diverse, ranging from medical devices and automotive parts to consumer electronics, allowing manufacturers to test product designs and iterate quickly before mass production.