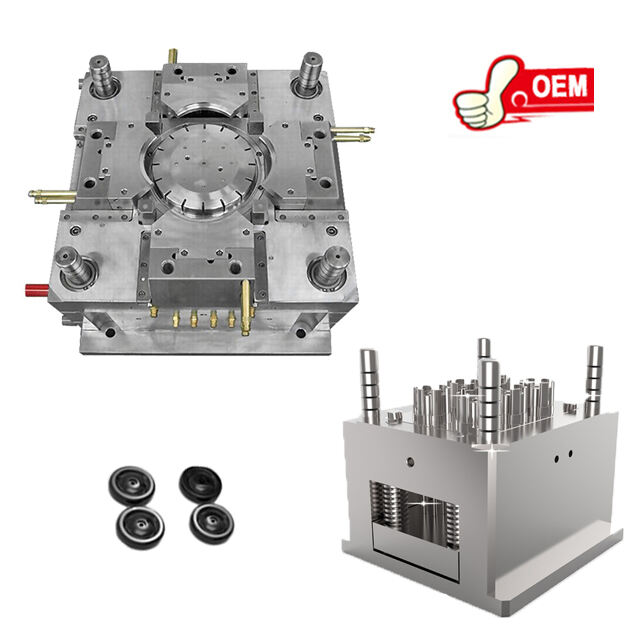

injection pallet

The injection pallet is an innovative piece of equipment designed for the manufacturing industry, predominantly used in plastic injection molding processes. Its main function is to hold and transport mold cavities and cores securely, ensuring precise placement within the injection molding machine. Technological features include a robust stainless steel construction for durability, precision engineering for tight tolerances, and advanced automation capabilities that enhance efficiency. The injection pallet is equipped with hydraulic or pneumatic systems that facilitate the movement and clamping of molds, which is crucial for maintaining high production rates. Its applications span various industries, from automotive to medical, where precision and reliability in manufacturing components are paramount.