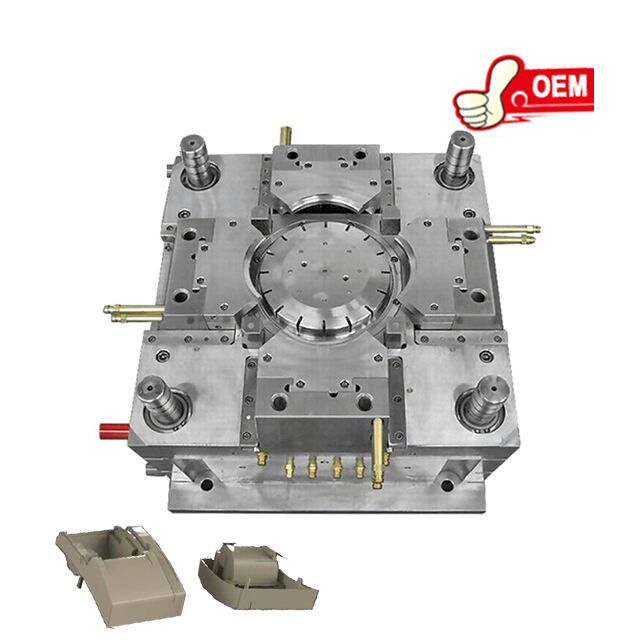

plastic mould die maker near me

Nestled conveniently close to you, our plastic mould die maker is a hub of advanced manufacturing processes. Specializing in crafting intricate and precise plastic moulds and dies, this facility performs a variety of essential functions that are integral to the production of plastic components. The main functions include design, prototyping, precision machining, and assembly, supported by cutting-edge CAD/CAM software and high-precision machinery. The technological features are highlighted by computer numerical controlled (CNC) machines, electric discharge machining (EDM) capabilities, and advanced surface treatments that ensure the moulds and dies are of the highest quality. These products find extensive applications across industries such as automotive, electronics, packaging, and medical devices, underlining the critical role the mould die maker plays in diverse manufacturing sectors.