low volume injection molding companies

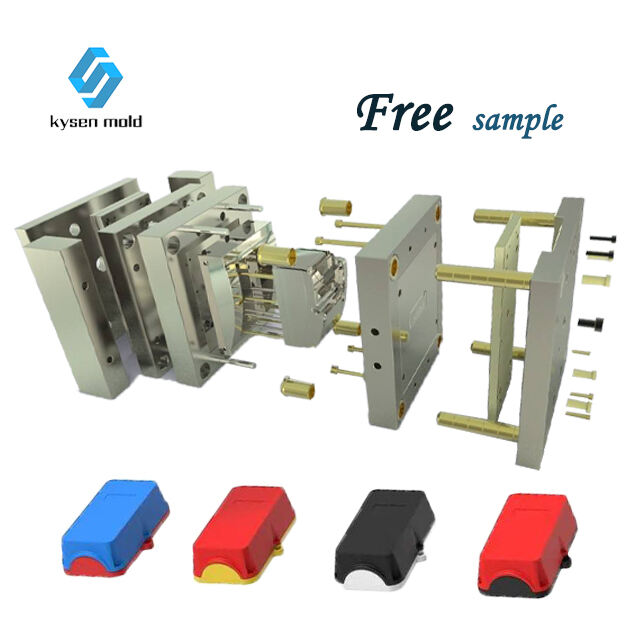

Low volume injection molding companies specialize in producing small to medium batches of plastic parts efficiently and cost-effectively. These companies utilize advanced molding machines that are capable of producing intricate designs with high precision and consistency. The main functions of these companies include mold design, material selection, production, and quality control. Technological features such as rapid prototyping and CAD/CAM software integration enable quick turnaround times and design modifications. Applications of low volume injection molding are diverse, ranging from medical devices and automotive parts to consumer electronics and aerospace components.