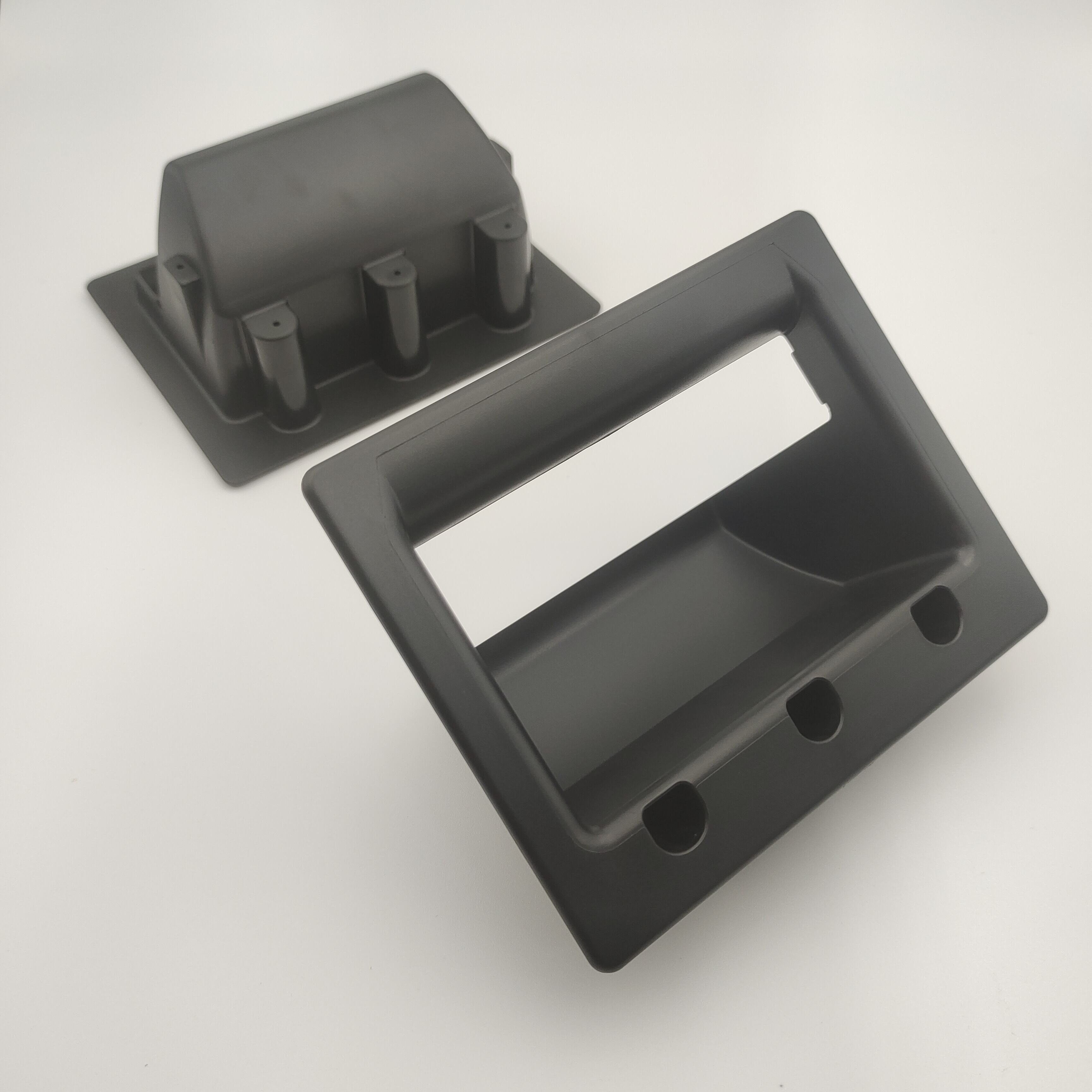

medical injection molding company

At our medical injection molding company, we specialize in precision molding processes that are integral to the healthcare industry. Our main functions include the design, development, and mass production of high-precision medical components and devices. We harness cutting-edge technology to ensure the highest levels of accuracy and consistency in our molding processes. Our advanced equipment and strict quality control measures allow us to produce intricate parts with tight tolerances. The applications of our products span across various medical sectors including surgical instruments, diagnostic devices, and drug delivery systems. We are committed to maintaining compliance with international medical standards, ensuring our products meet the stringent requirements of the industry.