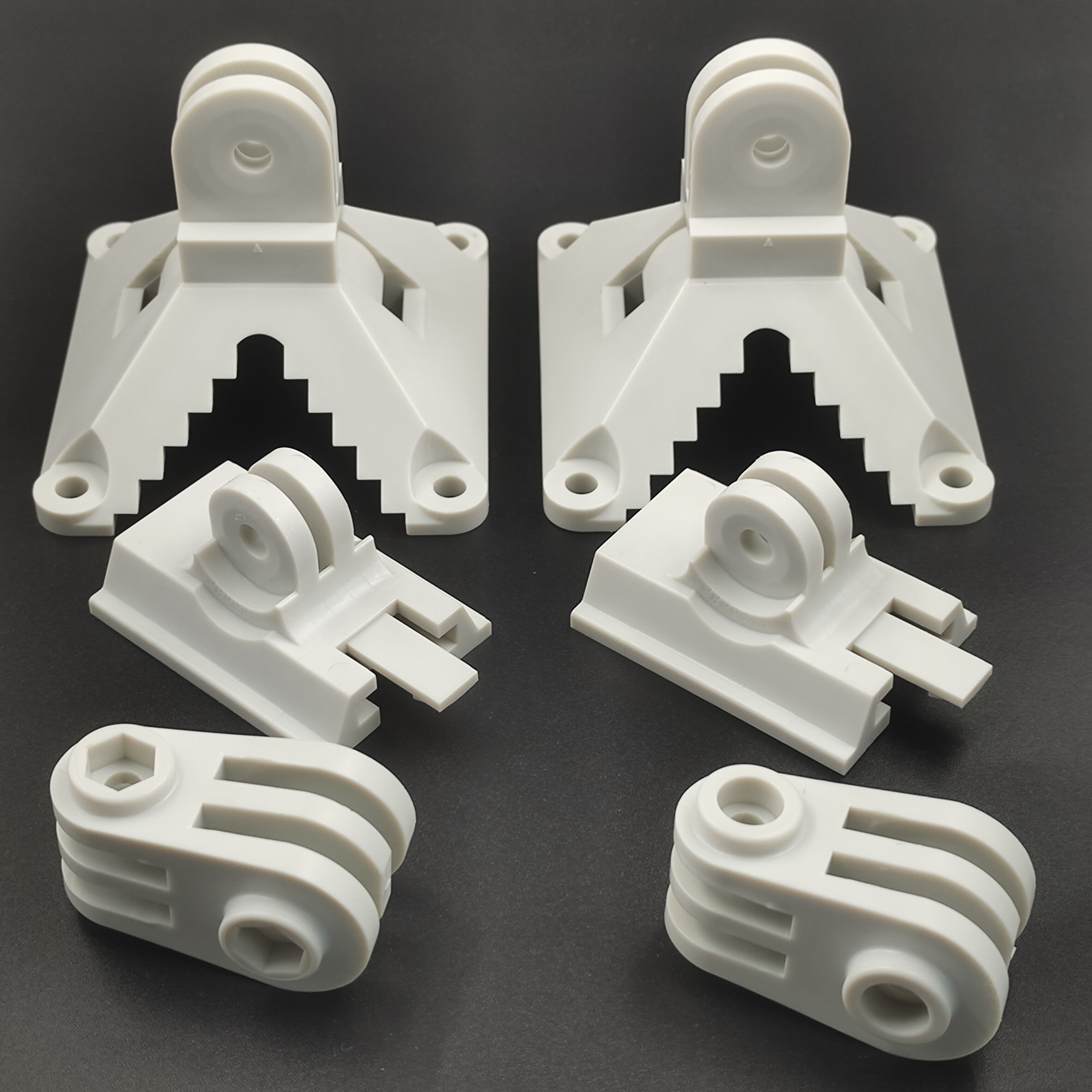

pe injection molding

PE injection molding, or Polyethylene injection molding, is a manufacturing process used to produce parts by injecting molten plastic material into a mold. The main functions of PE injection molding include shaping, forming, and producing high-volume parts with consistent quality. Technological features of this process encompass precision molds, advanced injection machinery, and automated systems that ensure efficiency and reliability. PE injection molding finds applications across various industries, including automotive, medical, consumer goods, and packaging, due to its versatility and the durability of the resulting products.