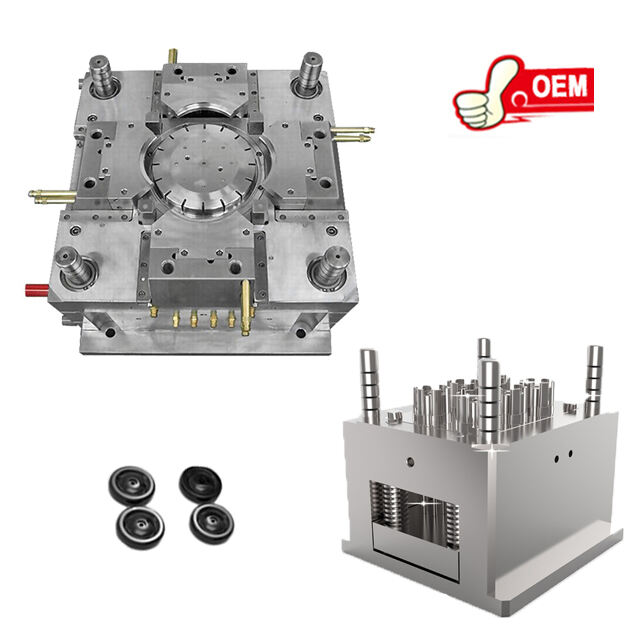

Material Diversity and Customization

Another standout feature is the extensive range of materials that can be used in the injection moulding process, coupled with the ability to customize these materials to meet specific application requirements. Plastic injection moulding components manufacturers offer a variety of thermoplastics, each with unique properties such as strength, flexibility, thermal resistance, and conductivity. This allows customers to tailor their products to exact specifications, optimizing performance and longevity. The customization does not stop at material selection; manufacturers can also engineer complex shapes and geometries, providing innovative solutions to design challenges.