plastic injection molding contract manufacturing

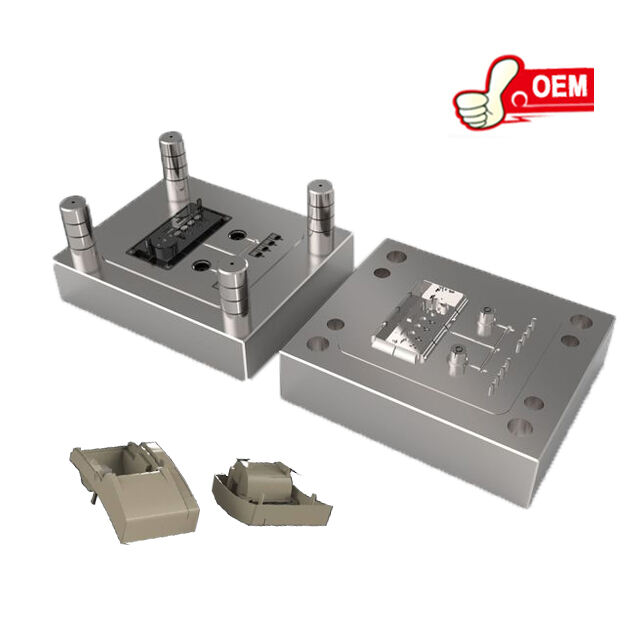

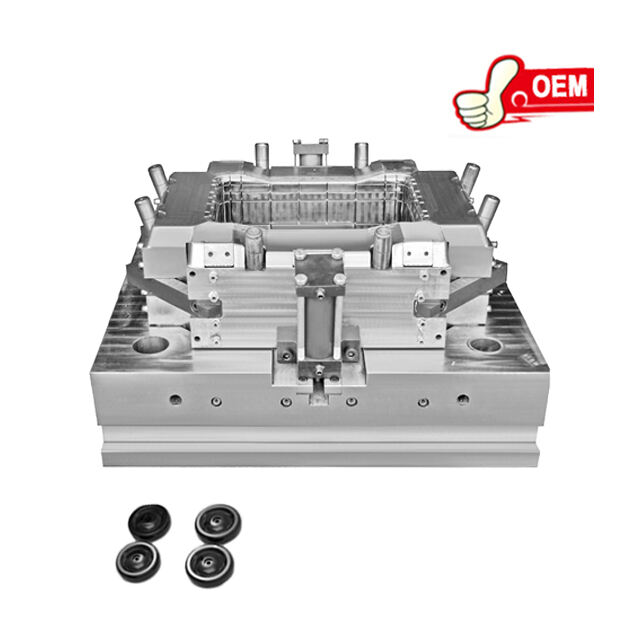

Plastic injection molding contract manufacturing is a specialized process that involves creating plastic parts by injecting molten material into a mold. The main function of this process is to produce high volumes of identical plastic components efficiently and with high precision. Technological features of plastic injection molding include the use of advanced molding machines, automated robotics, and sophisticated control systems to ensure consistent quality. These components are used in a wide range of industries, from automotive and electronics to medical devices and consumer goods. The process begins with the design and creation of a mold, followed by the injection of melted plastic into the cavity. Once cooled, the part is ejected, trimmed, and ready for use or further assembly.