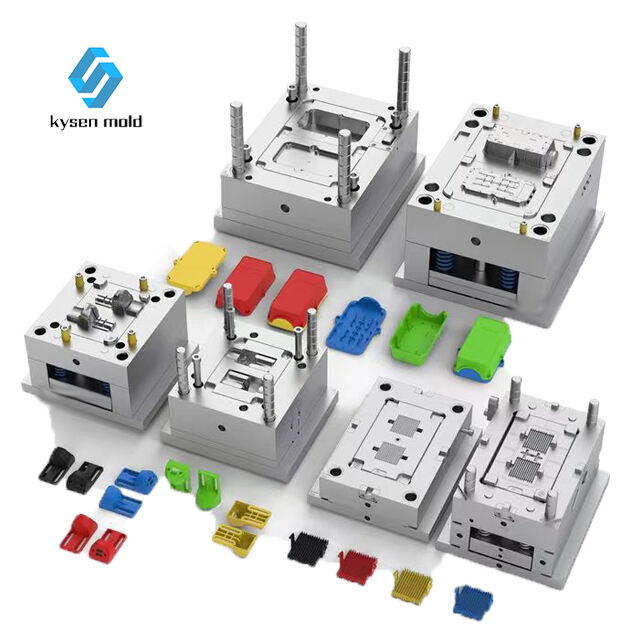

plastic moulding suppliers

Plastic moulding suppliers are pivotal to the manufacturing industry, providing the essential means to shape plastic into a myriad of products we use daily. These suppliers offer advanced machines and molds that are designed to inject, compression, or blow mold plastics into the desired forms. Main functions include designing molds tailored to product specifications, selecting the appropriate type of plastic, and precision engineering to ensure high-quality output. Technological features of these suppliers often encompass computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, robotics, and automated quality control mechanisms, which all work in synergy to deliver accurate and consistent results. Applications span across automotive, medical, consumer goods, and electronic sectors, highlighting the indispensable role plastic moulding plays in modern manufacturing.