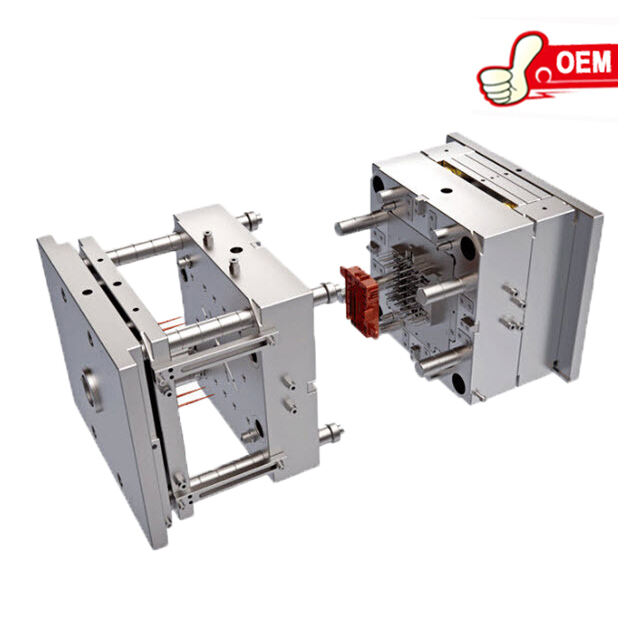

injection moulding die maker

An injection moulding die maker is a sophisticated piece of equipment used in the manufacturing industry to create the molds required for plastic injection molding. Its main function is to shape molten plastic into desired forms through the use of precision molds and advanced control systems. Technological features of these machines include programmable logic controllers for precise operation, automated robotics for handling and assembly, and advanced temperature control systems that ensure consistent material properties. These die makers are used across various industries, from automotive to medical, for producing a vast range of products such as plastic components, packaging, and consumer goods.