3d injection molding

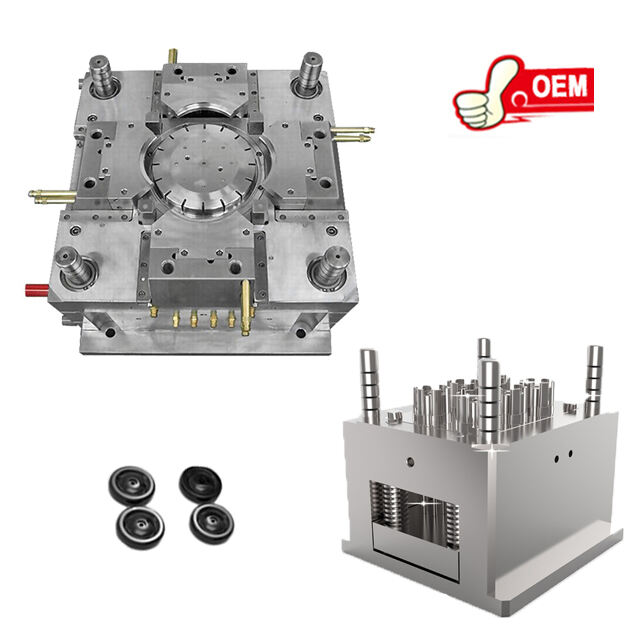

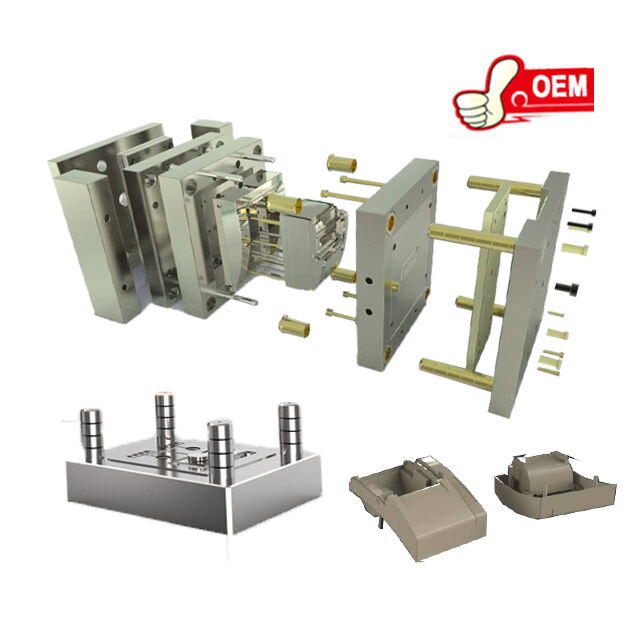

3D injection molding is a sophisticated manufacturing process that involves injecting molten material into a mold to create a three-dimensional object. The main functions of 3D injection molding include producing complex shapes, high precision parts, and intricate designs with consistency and repeatability. Technological features such as computer-aided design (CAD) and automated machinery enable precise control over the molding process. This process is used across various industries for producing anything from small medical devices to large automotive parts. The mold, typically made of steel or aluminum, is carefully designed to ensure the final product meets exact specifications. Once the mold is created, the injection molding machine heats the material until it reaches a molten state, then injects it into the mold cavity. After cooling, the solidified part is ejected, ready for use or further assembly.