aluminum injection mold company

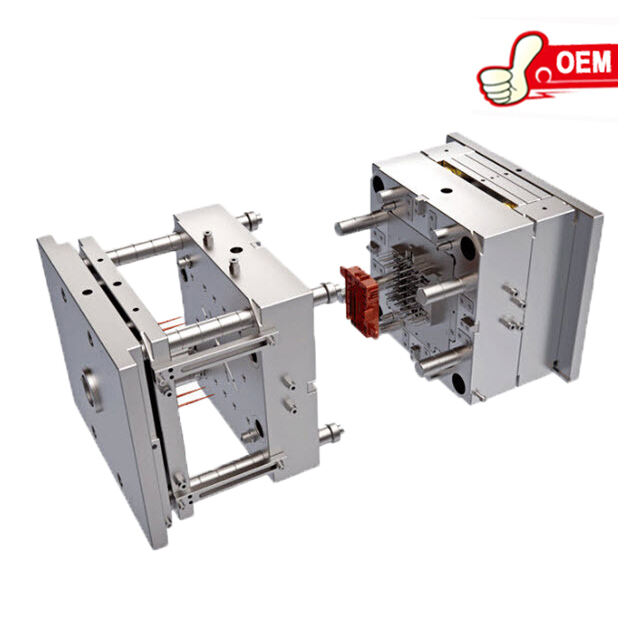

At the heart of modern manufacturing, our aluminum injection mold company stands as a beacon of innovation and precision. Specializing in the creation of high-quality molds, our main functions include the design, engineering, and production of aluminum molds tailored for plastic injection molding. These molds are crafted with state-of-the-art technology, offering intricate details and superior surface finishes. Our cutting-edge equipment ensures tight tolerances and excellent thermal conductivity, making our molds ideal for producing complex parts with high consistency. The applications of our molds span across various industries, including automotive, aerospace, medical, and consumer electronics, where precision and efficiency are non-negotiable.