custom injection molding cost

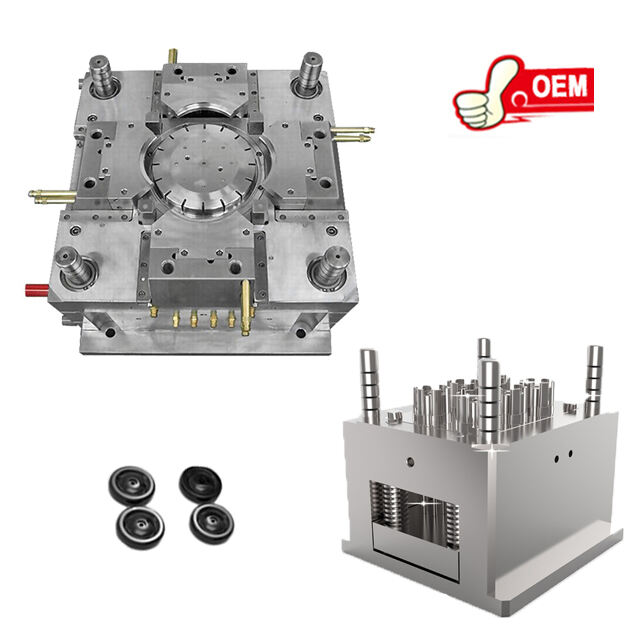

Understanding the custom injection molding cost involves exploring its main functions, technological features, and diverse applications. Custom injection molding is a manufacturing process that produces parts by injecting molten material into a mold. The cost associated with it encompasses the design, materials, mold creation, and the actual molding process. Main functions include creating precise and complex shapes that are difficult to achieve with other methods. Technological features such as the use of advanced polymers and automated systems ensure high efficiency and consistency. This process is widely used across industries like automotive, medical, electronics, and consumer goods, where intricate and durable parts are required.