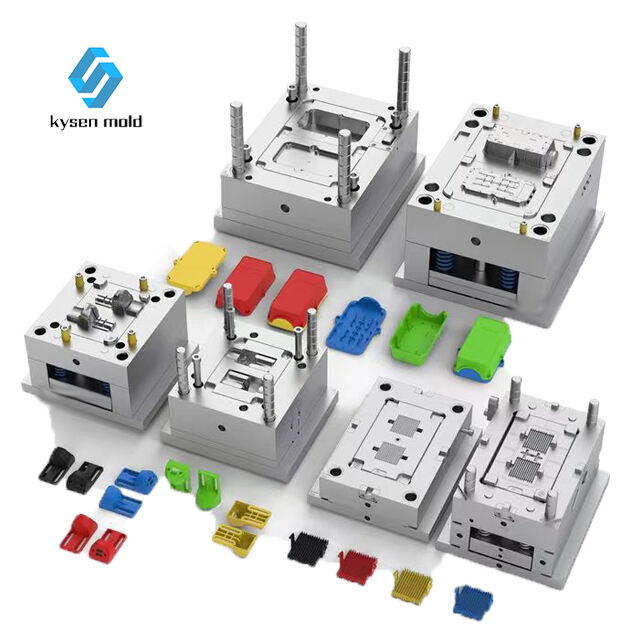

plastic injection molding business for sale

This plastic injection molding business for sale is a robust operation designed to meet the precise demands of the manufacturing industry. Specializing in the creation of high-quality plastic components, its main functions include mold design, material selection, injection molding, and post-molding finishing. Technological features encompass state-of-the-art injection molding machines equipped with sophisticated control systems, ensuring precision and efficiency. The business serves a wide range of applications, from automotive and electronic parts to medical devices and consumer goods, offering versatility and adaptability to various industries.