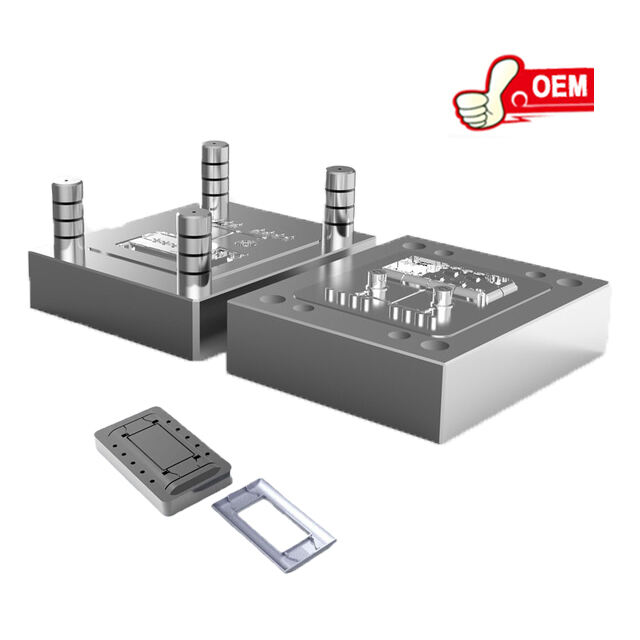

injection mold components suppliers

Injection mold components suppliers are vital to the manufacturing industry, providing the essential parts needed for the injection molding process. The main functions of these suppliers include designing, manufacturing, and distributing precision components that form the various parts of an injection mold. Technological features of these components encompass high durability, precision engineering, and the ability to withstand high temperatures and pressures. Applications of injection mold components are widespread, ranging from automotive parts and electronic devices to medical equipment and consumer goods. The precision and reliability of these components are crucial in ensuring the quality and efficiency of the final products.