plastic injection molding at home

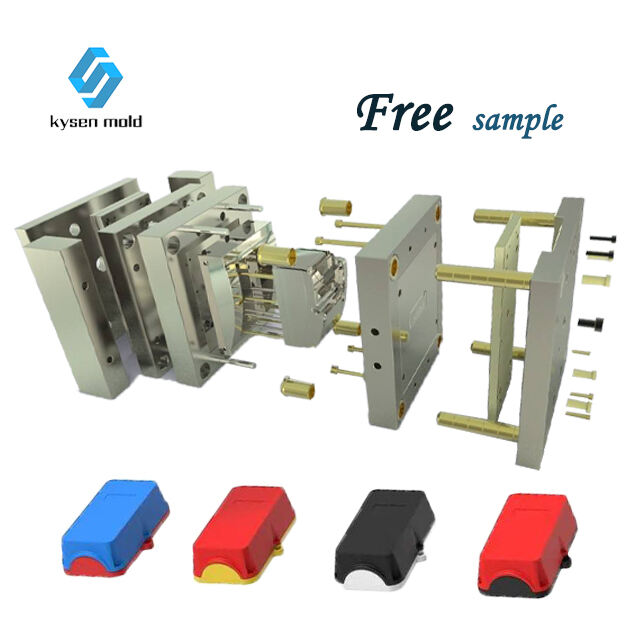

Plastic injection molding at home is a revolutionary technique that allows for the efficient and precise production of plastic parts. The main function of this process is to inject molten plastic into a mold cavity, where it cools and solidifies to the desired shape. Technological features include programmable control systems, high-pressure injection capabilities, and automated part removal. This makes it suitable for a wide range of applications, from manufacturing consumer goods to producing intricate components for various industries. The process is known for its high repeatability, allowing for consistent quality in mass production.