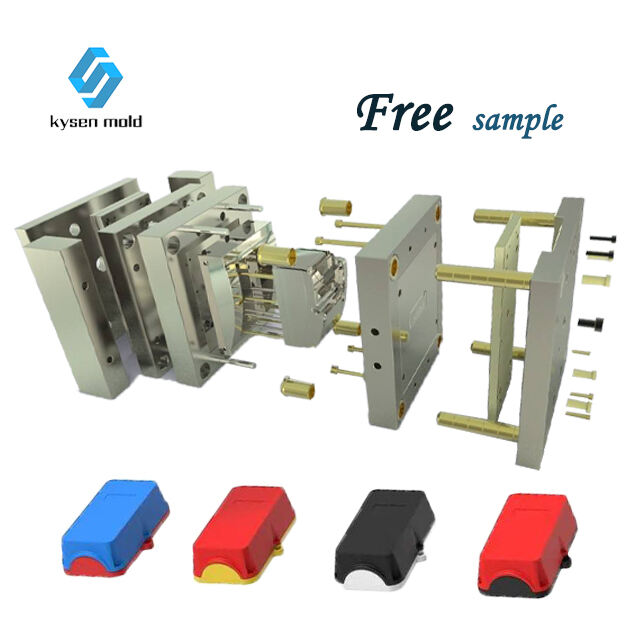

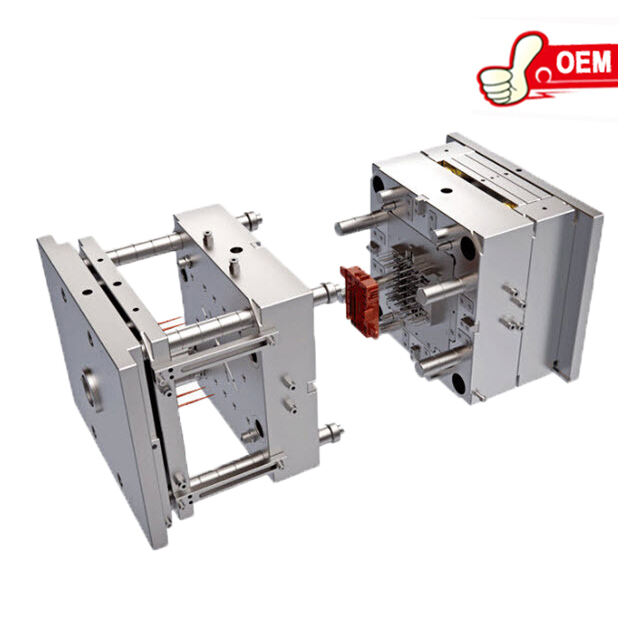

injection molding small parts

Injection molding small parts is a precision manufacturing process that involves injecting molten material into a mold cavity to produce intricate parts with high precision. The main functions of this process include shaping, forming, and fabricating complex components that are crucial for various industries. Technological features of injection molding small parts encompass the use of advanced machinery, precision molds, and automated systems to ensure consistency and quality. The materials commonly used range from plastics to metals, and the resulting parts are characterized by their durability, accuracy, and fine details. These small parts find extensive applications in the automotive, medical, aerospace, and electronic sectors, serving as essential components in devices, equipment, and machinery.