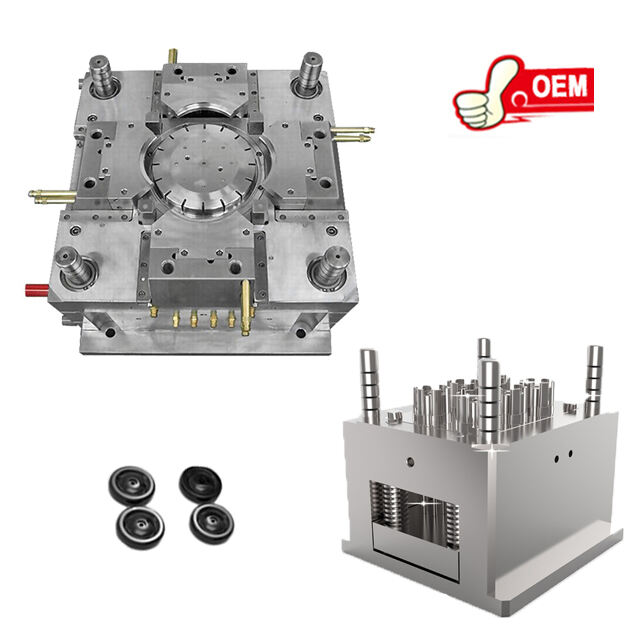

small molded parts

Small molded parts are intricate components that play pivotal roles in various industries. These parts are produced through precision molding processes and are characterized by their compact size, accuracy, and high-quality finish. Main functions of small molded parts include serving as connectors, hinges, seals, and structural components within larger assemblies. Technologically, they are designed with tight tolerances to ensure a perfect fit and are often crafted from durable plastics or metals that withstand harsh conditions. Their applications span across automotive, aerospace, medical devices, consumer electronics, and more, where they are integral for the reliable operation and extended lifespan of the products.