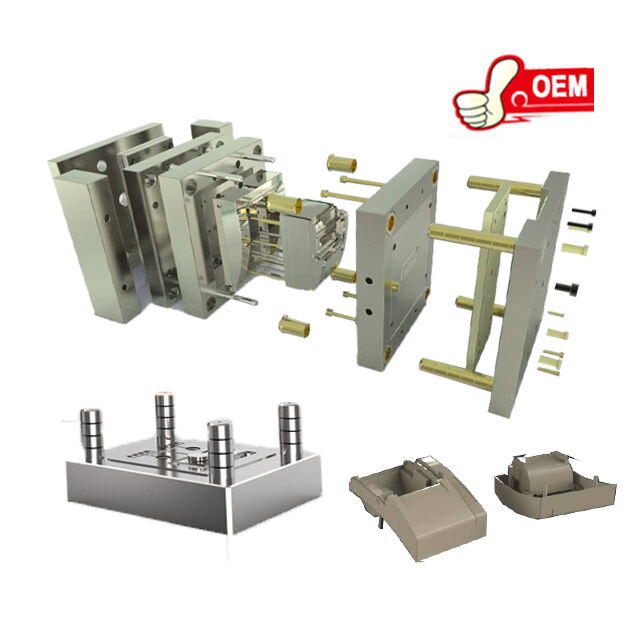

injection moulding components manufacturers

Injection moulding components manufacturers are at the forefront of producing intricate parts for a myriad of industries. These manufacturers utilize advanced machinery to inject molten plastic into a mould, where it cools and solidifies to the desired shape. The main functions include designing the moulds, selecting the appropriate plastics, and operating the injection moulding machines. Technological features such as precision engineering, automated processes, and computer-aided design ensure high-quality production. Applications span across automotive, medical, consumer goods, and electronics sectors, where precision and consistency are paramount.