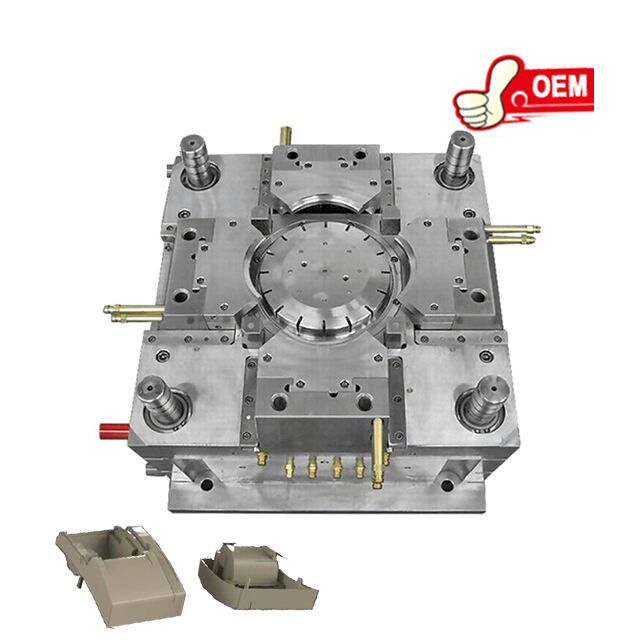

large scale injection moulding

Large scale injection moulding is a high-volume manufacturing process that involves injecting molten material into a mould to produce parts in large quantities. The main functions of this process include shaping, forming, and producing intricate details in plastic components. Technological features such as high-pressure injection, automated machinery, and precise temperature control ensure consistent quality and high productivity. Large scale injection moulding finds extensive applications across various industries, including automotive, electronics, packaging, and consumer goods, where high-volume production is essential.