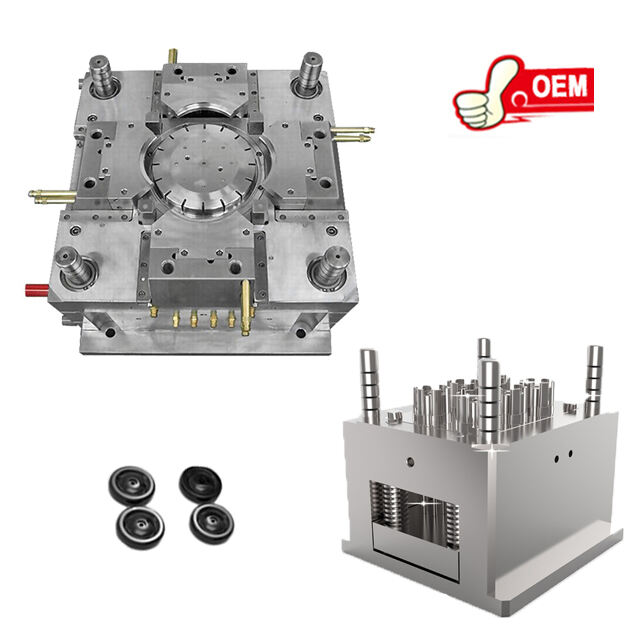

plastic injection mold

The plastic injection mold is a crucial tool in the manufacturing industry, designed to shape molten plastic into desired forms. Its main function is to produce high volumes of identical plastic parts efficiently and with precision. Technological features include a cavity where the plastic is injected, a runner system for material flow, and a cooling system to solidify the product quickly. These molds are programmable for various intricate designs and are commonly used in industries ranging from automotive to consumer electronics. The precision and speed of the injection molding process make it ideal for mass production, offering consistent quality and intricate detail in every piece produced.