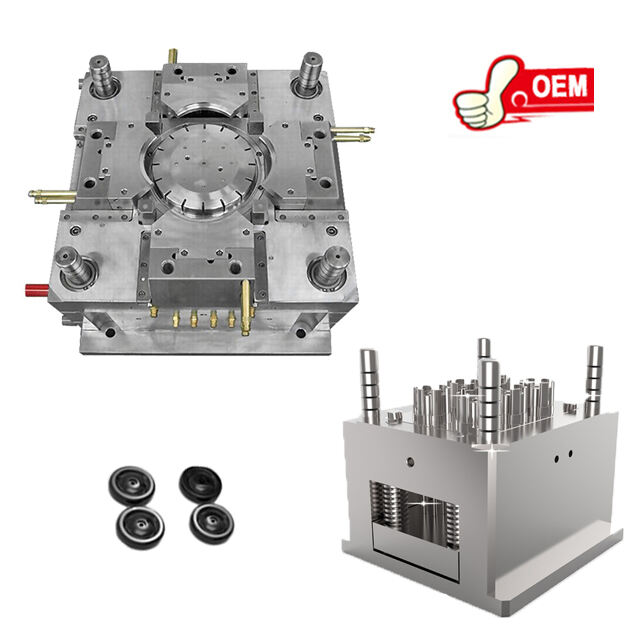

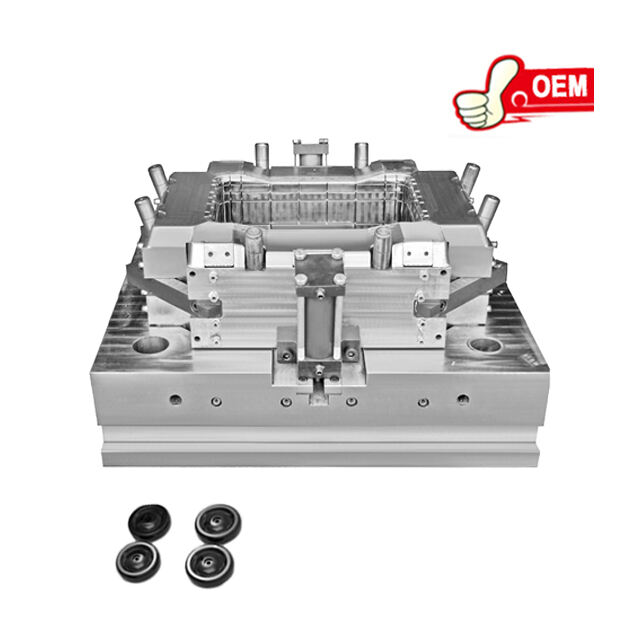

plastic injection mold fabrication

Plastic injection mold fabrication is a precision engineering process that involves creating molds used for producing plastic parts. The main functions of these molds are to shape, core, and cavity the molten plastic into the desired form. Technological features include the use of high-quality steel, precise design specifications, and advanced machining processes. These molds are used in a wide range of applications, from automotive parts to consumer electronics, medical devices, and more. The process begins with mold design, followed by CNC machining, polishing, and assembly, ensuring the mold is capable of producing intricate and precise parts at high volumes.