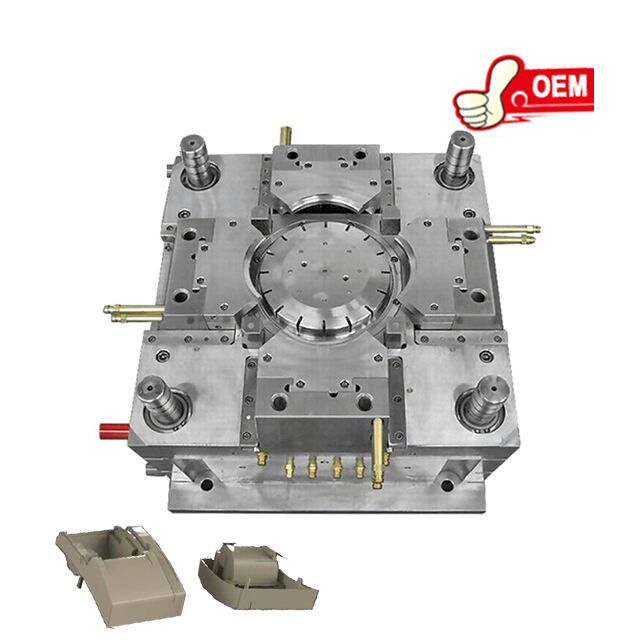

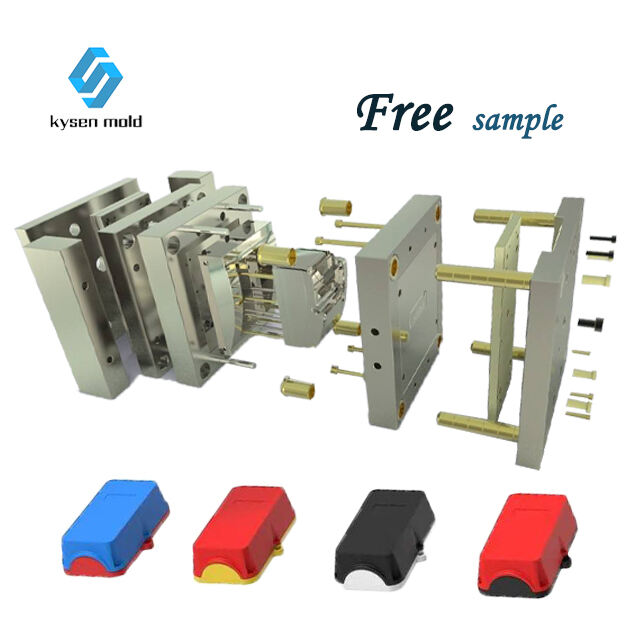

industrial mould

The industrial mould is a critical component in the manufacturing industry that serves as a cavity or form in which a liquid or plastic material is shaped into a desired product. Its main functions include shaping, forming, and maintaining the integrity of a product's design during the production process. Technologically advanced features such as precision engineering, high wear resistance, and the ability to withstand extreme temperatures are integral to the mould's performance. These features enable the mould to produce parts with tight tolerances and complex geometries. The applications of industrial moulds are vast, ranging from automotive parts and electronics to medical devices and consumer goods, highlighting their versatility and necessity in various industries.