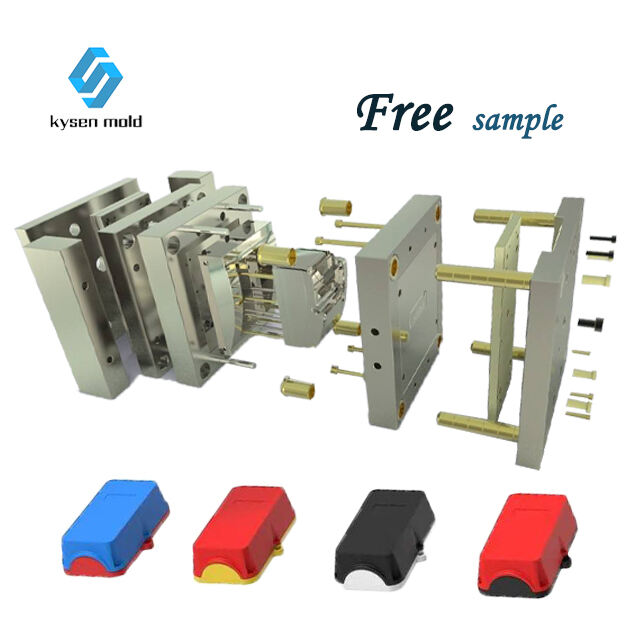

plastic molding prototype making

Plastic molding prototype making is a crucial process in the development of new plastic products. It involves creating a preliminary model or sample of the final product using various molding techniques. The main functions of plastic molding prototypes include testing product design, assessing functionality, and refining the manufacturing process. Technological features of this process involve the use of advanced CAD software for design, precise machinery for mold creation, and a variety of molding methods such as injection molding, blow molding, and rotational molding. These prototypes are essential in various industries, from automotive and electronics to medical devices and consumer goods, as they allow manufacturers to detect and correct design flaws before mass production.