plastic moulding cost

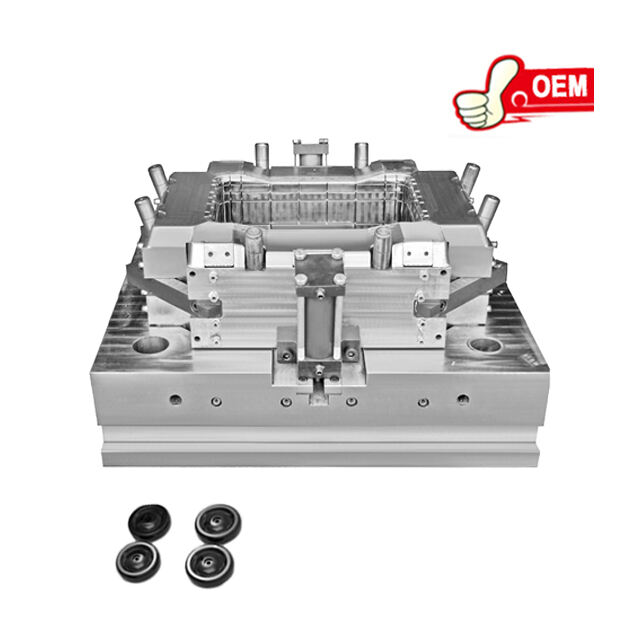

Understanding the plastic moulding cost involves recognizing its primary functions, technological features, and diverse applications. Plastic moulding is a manufacturing process that shapes molten plastic into a specific form using a mould cavity. The cost associated with it encompasses various factors such as the complexity of the design, the material used, and the machinery involved. Main functions of plastic moulding include producing intricate shapes, high volume production, and creating products that are durable and cost-effective. Technological features include the use of advanced injection moulding machines, robotics for automation, and computer-aided design for precision. Applications span across industries from automotive and electronics to medical devices and consumer goods, making it an indispensable process in modern manufacturing.