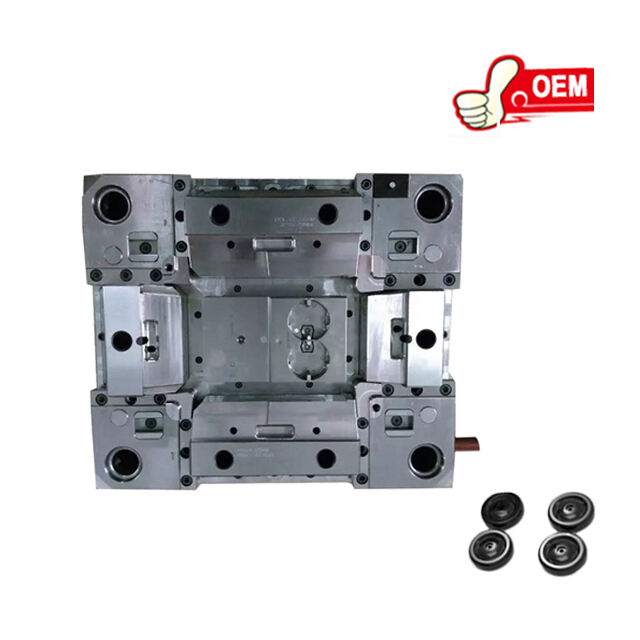

rapid prototyping plastic injection molding

Rapid prototyping plastic injection molding is a cutting-edge technology used to quickly and efficiently create precise plastic parts and prototypes. The main functions of this process include the creation of intricate designs, the production of high-strength parts, and the facilitation of mass production. Technological features such as computer-aided design (CAD) and automated machinery enable the precise shaping of plastics into the desired form. This process is widely used in various industries including automotive, electronics, healthcare, and consumer goods. Applications range from producing complex medical devices to intricate consumer electronics, showcasing its versatility and importance in modern manufacturing.