scientific injection molding

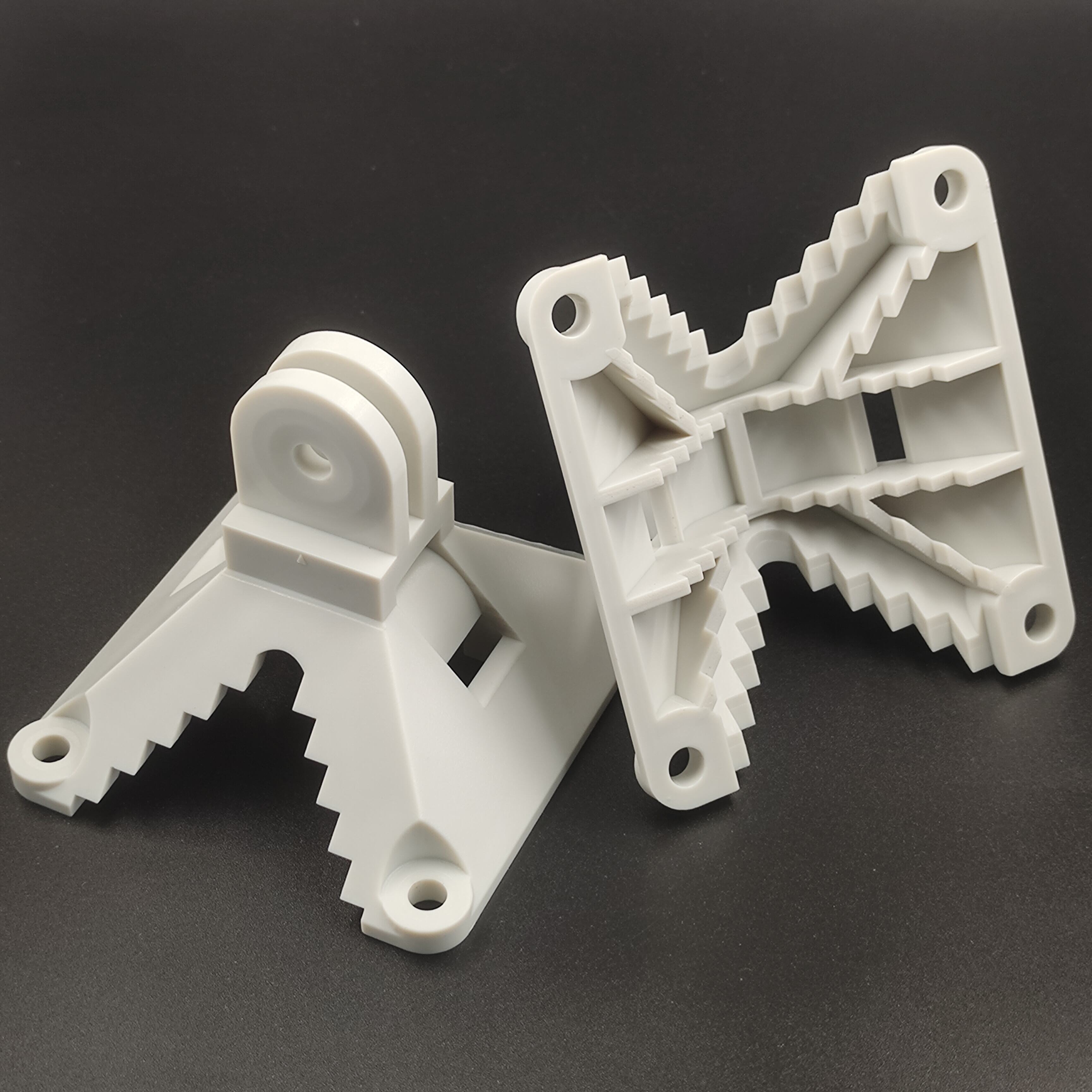

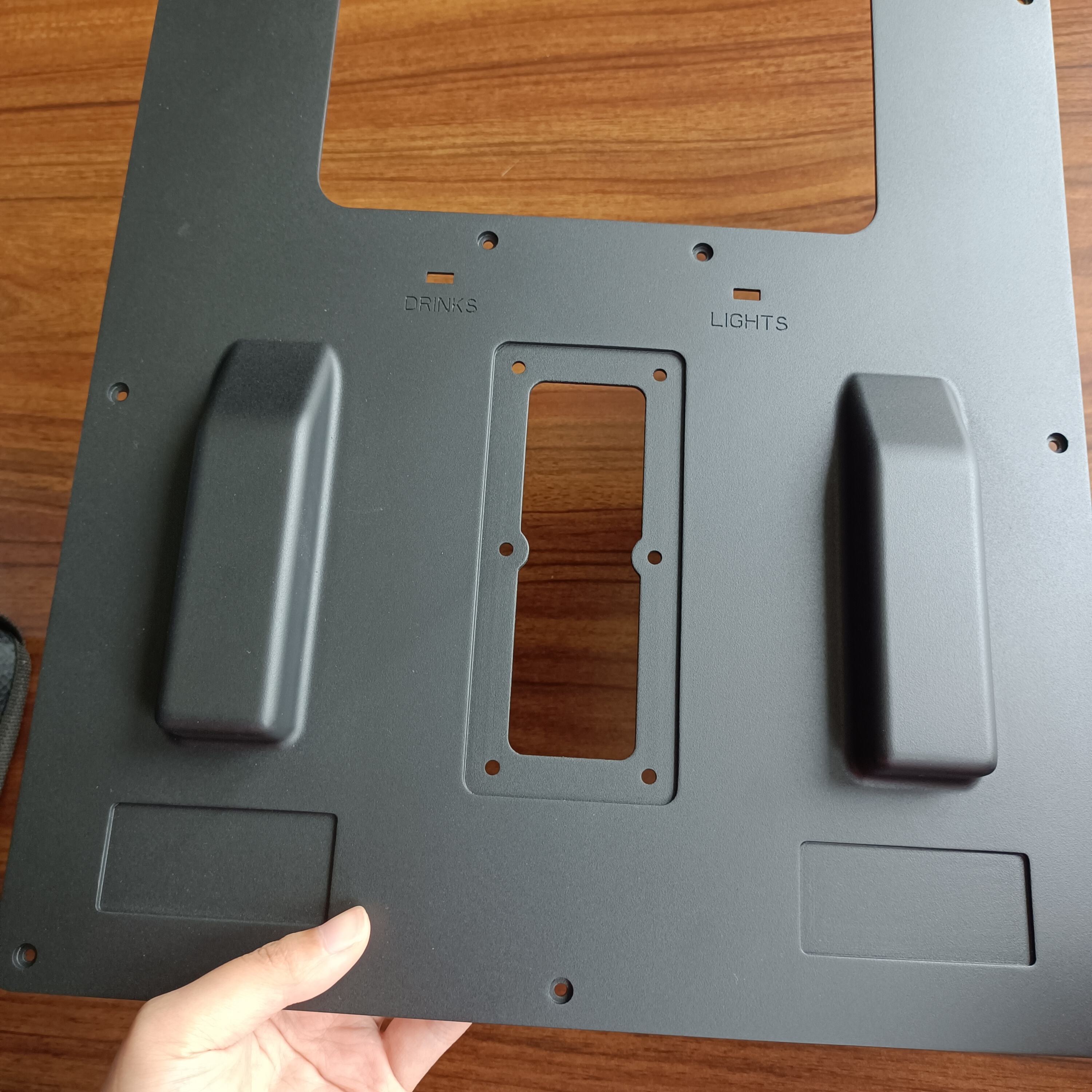

Scientific injection molding is a precision engineering process that leverages advanced technology to create high-quality plastic parts. The main functions of this process include injecting molten plastic into a mold, cooling it to a solid state, and then ejecting the final product. Technological features such as computer-aided design (CAD), precise temperature control, and robotic automation are integral to achieving consistent and intricate designs. This process is widely used in various industries including automotive, medical, and consumer goods, where intricate and precise components are required. The applications are vast, from producing tiny medical devices to intricate automotive parts and large consumer products.