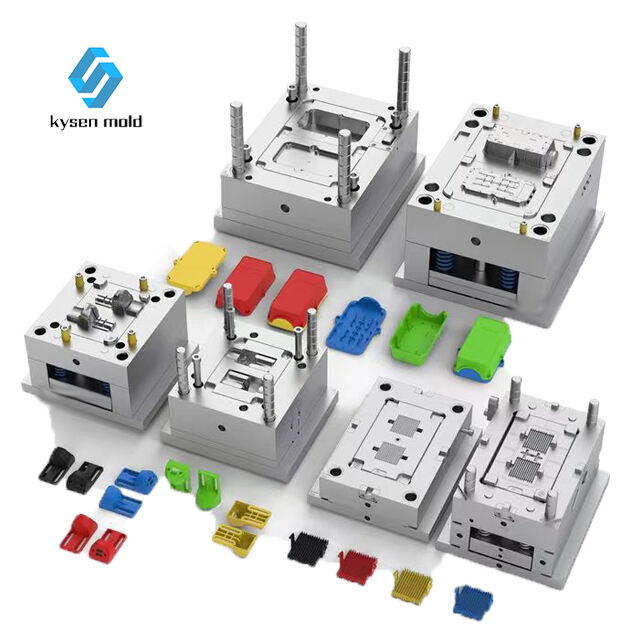

short mould in injection moulding

The short mould in injection moulding is a critical component designed to produce small, intricate plastic parts efficiently. Its main functions include injecting molten material into a cavity, cooling it rapidly to form the desired shape, and then ejecting the finished product. Technological features of the short mould include compact design, precise cavity dimensions, and rapid cycle times. These features make it ideal for applications where high precision and fast production rates are essential, such as in the medical, automotive, and electronics industries.