best injection molding companies

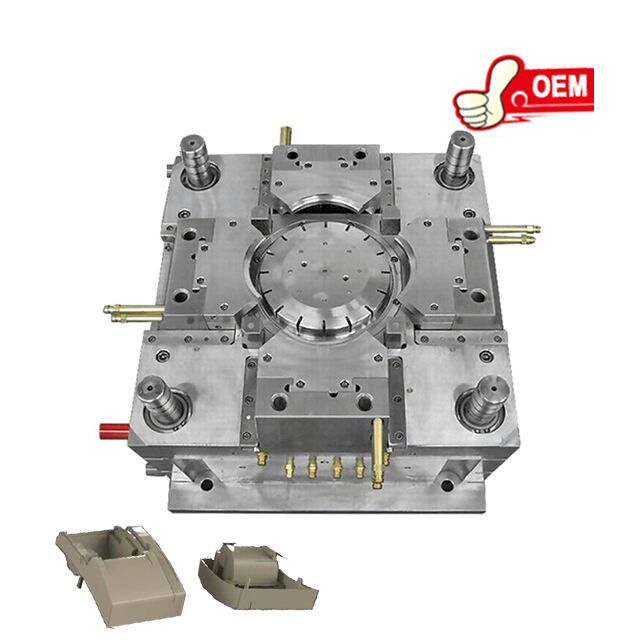

The premier injection molding companies are distinguished by their exceptional capabilities in producing high-quality plastic components. These companies specialize in the intricate art of injection molding, a process that involves injecting molten material into a mold, then cooling and solidifying it to obtain the desired shape. Their main functions encompass the design and production of molds, material selection, and precision manufacturing. Technological features include state-of-the-art machinery, robotic automation, and advanced monitoring systems that ensure precision and consistency. The applications are vast, ranging from automotive parts and medical devices to consumer electronics and packaging, reflecting the versatility and demand for expert injection molding services.