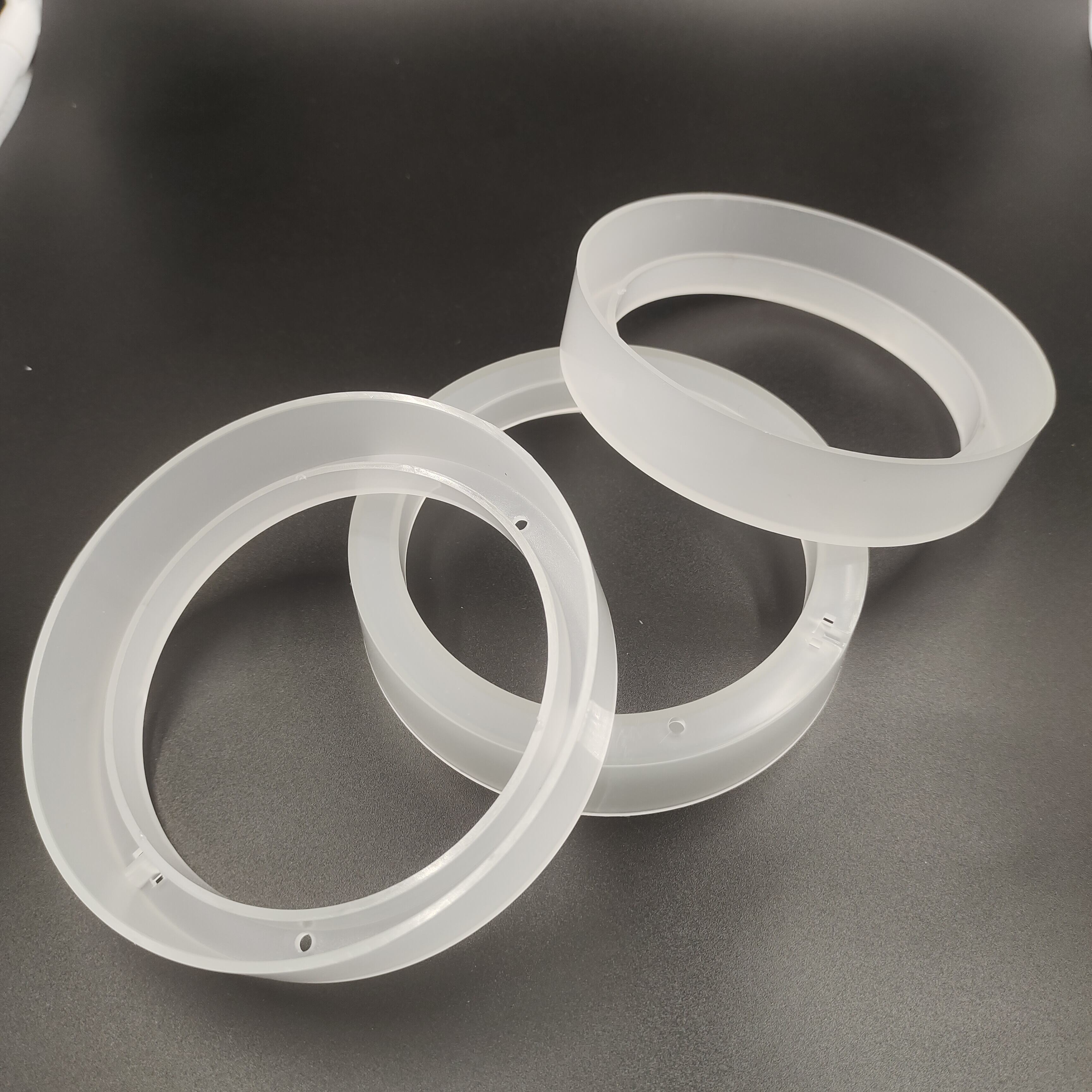

short run injection moulding

Short run injection moulding is a versatile process in the manufacturing industry, primarily used for producing plastic parts and components in smaller batch quantities. Its main functions include moulding plastic materials into the desired shape with high precision and speed. Technological features of short run injection moulding encompass the use of specialized moulds and injection moulding machines that can rapidly produce parts with intricate details and complex geometries. This process is highly adaptable, allowing for swift changes between different part types. Applications of short run injection moulding are extensive, ranging from automotive and medical industries to consumer goods and electronics, where fast production and flexibility are crucial.