silicone injection molding companies

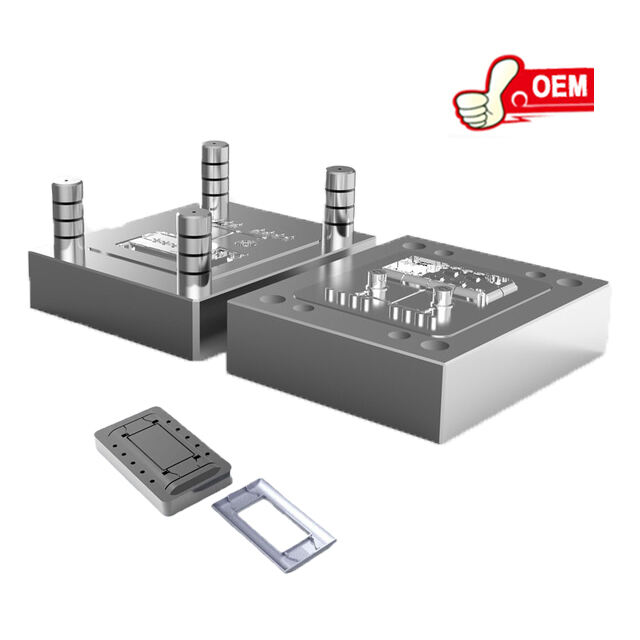

Silicone injection molding companies specialize in the precise and efficient production of silicone-based products through a sophisticated injection molding process. At the core, these companies handle the design, tooling, and mass production of parts that require the flexibility and durability of silicone. Utilizing advanced machinery and precision molds, they can produce items with intricate details and consistent quality. Main functions include custom mold creation, material selection, and the actual injection molding process, which is characterized by high-pressure injection of liquid silicone rubber into a mold cavity. Technological features encompass automated systems, temperature control, and robotic assistance, ensuring high yields and minimal waste. The applications span across various industries, including healthcare, automotive, consumer electronics, and home appliances, where silicone components are integral for their performance and longevity.