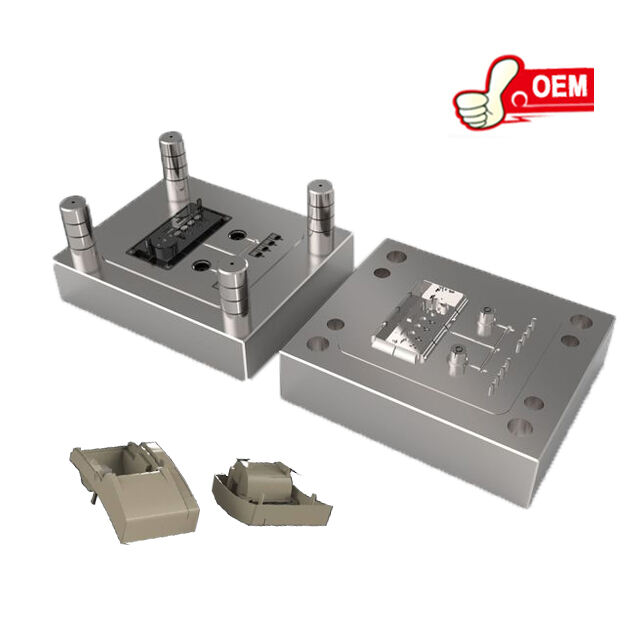

small run plastic injection molding

Small run plastic injection molding is a specialized process designed for producing smaller quantities of plastic parts efficiently. Its main function is to create precise and intricate plastic components quickly and at a lower cost than traditional large-scale injection molding. Technological features include the use of advanced machinery that allows for rapid tooling changes and shorter production cycles, making it ideal for prototyping and low-volume production runs. The applications of small run plastic injection molding are diverse, ranging from medical devices and automotive parts to consumer electronics and household goods, offering flexibility for a variety of industries.