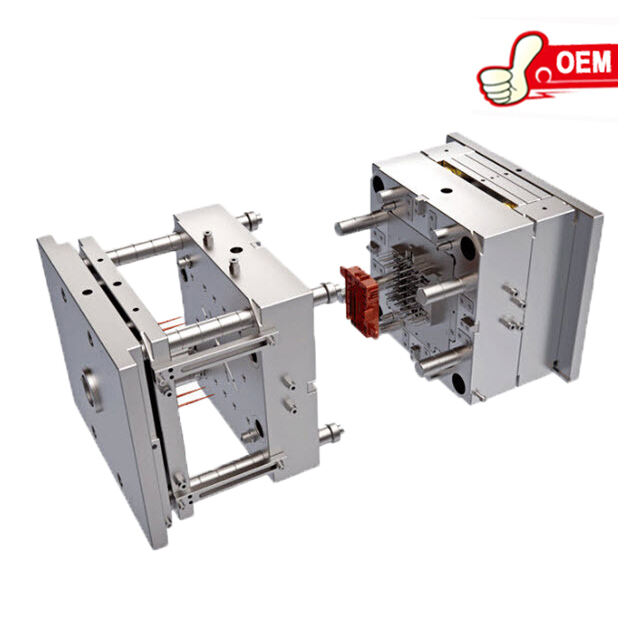

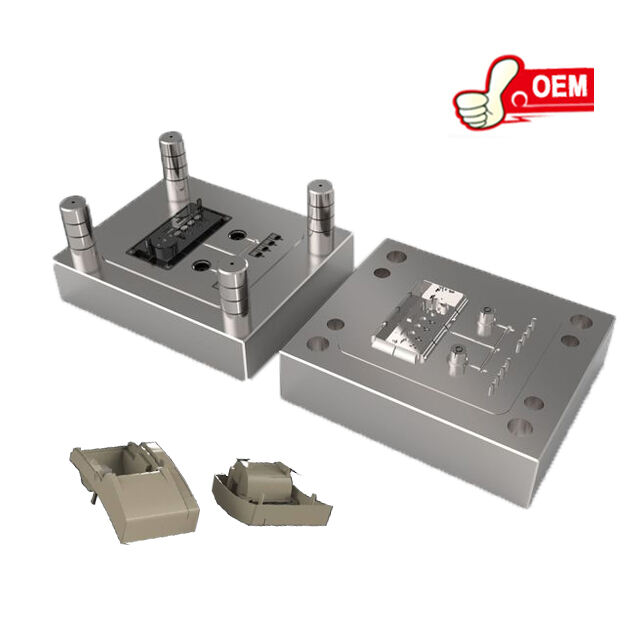

injection mold manufacturing companies

Injection mold manufacturing companies are at the forefront of producing precision tools essential for the mass production of plastic parts and components. These companies specialize in designing and crafting molds that shape melted plastic into intricate and specific designs when injected into a mold cavity. The main functions of these companies include mold design, precision engineering, material selection, and quality control. Technological features of modern injection mold manufacturing include the use of CAD/CAM software for design, high-speed CNC machining for precise mold creation, and advanced robotics for automation. These companies serve industries ranging from automotive to healthcare, providing tailored solutions for a diverse array of applications, from vehicle parts to medical devices.