automotive injection molding companies

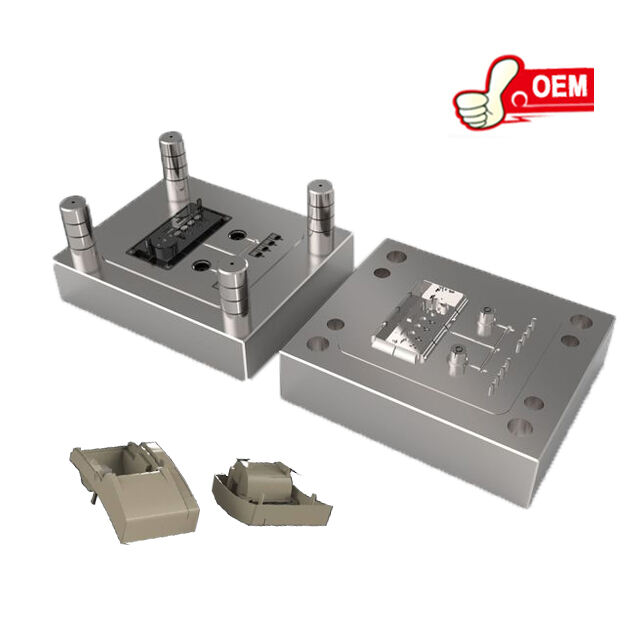

Automotive injection molding companies specialize in producing high precision parts for the automotive industry through the injection molding process. This involves injecting molten plastic into a mold cavity, where it cools and solidifies to the desired shape. These companies' main functions include designing molds, selecting appropriate plastics, and manufacturing parts that meet stringent quality standards. Technological features of these companies encompass advanced molding machines, robotics for automation, and sophisticated software for mold design and process control. Their applications range from producing vehicle interiors, exterior components, under-the-hood parts, to electrical connectors and more, all of which are critical for car functionality, safety, and aesthetics.