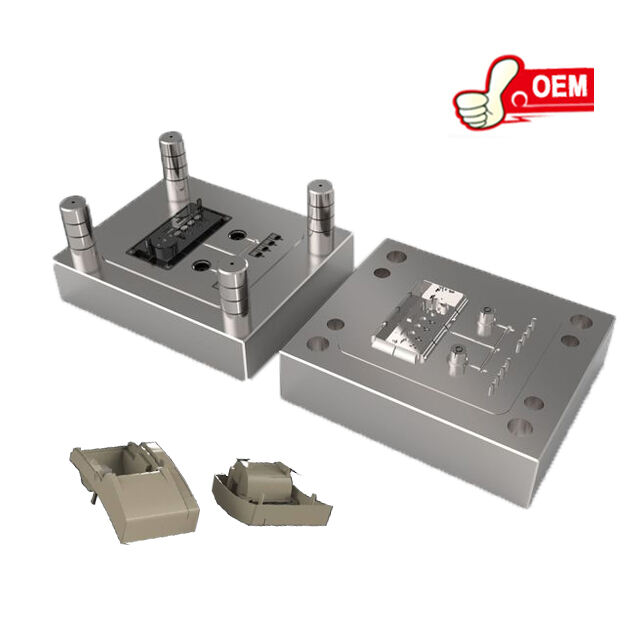

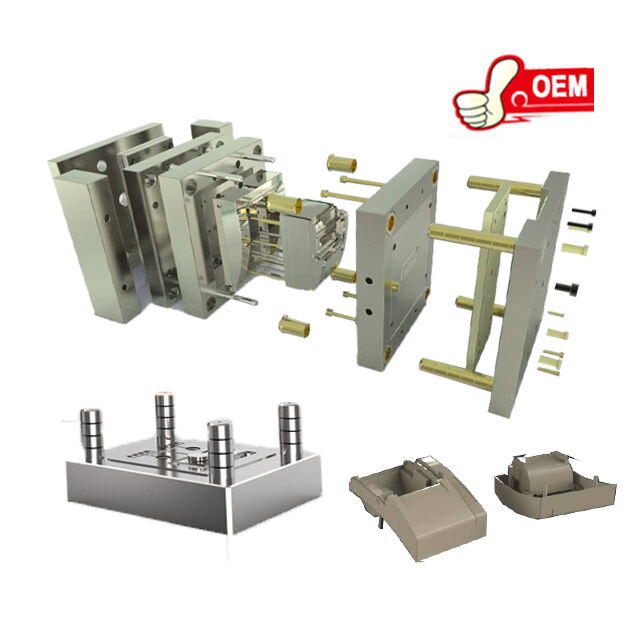

automotive plastic injection molding companies

Automotive plastic injection molding companies specialize in producing intricate plastic components for the automotive industry. These companies utilize advanced injection molding machines to melt plastic pellets and inject them into metal molds, where they cool and solidify into the desired shape. Main functions include designing molds, selecting the appropriate materials, and manufacturing high-volume parts quickly and efficiently. Technological features of these companies often include computer-aided design (CAD) software for precise mold design, automated robotics for handling and assembly, and sophisticated quality control systems. Applications span a wide range of automotive parts, from interior trims and dashboard components to exterior parts like bumpers and lighting assemblies.