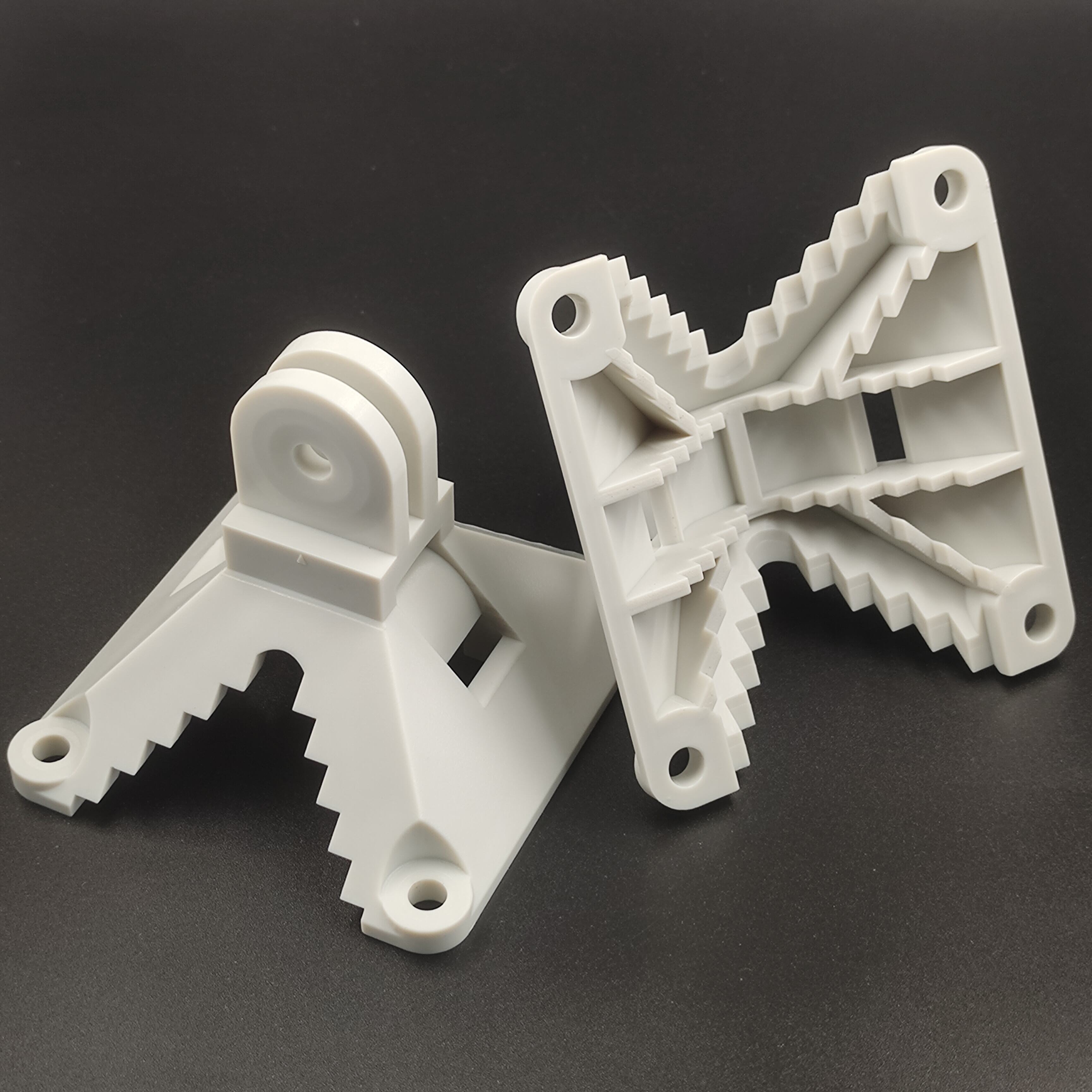

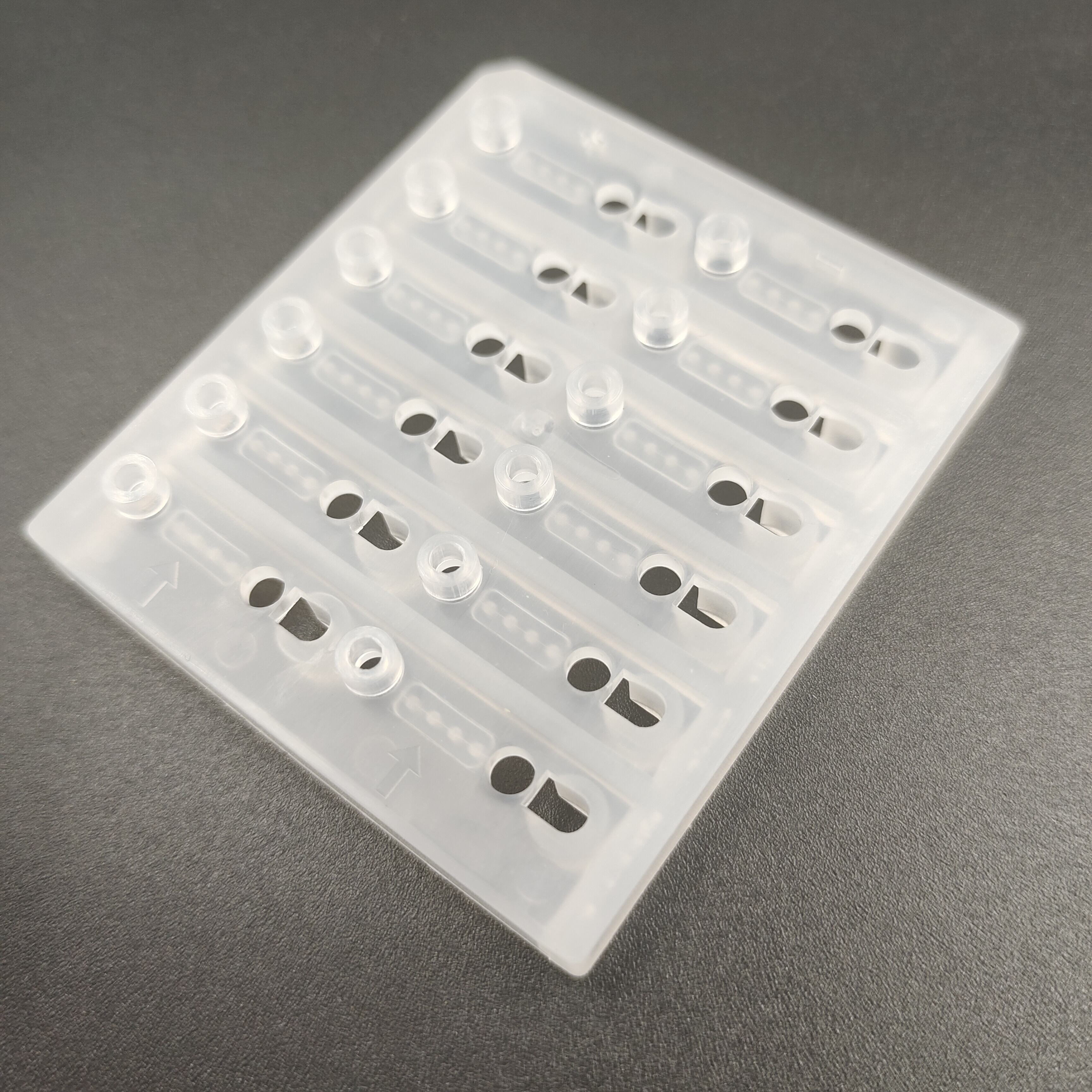

Material Versatility

The versatility of materials used in basic injection molding is another of its unique selling points. This process is compatible with a broad spectrum of materials, including various plastics, metals, and elastomers. This flexibility allows manufacturers to produce parts that cater to diverse applications and performance requirements. By being able to select the most appropriate material for a specific application, customers can optimize the balance between cost, functionality, and durability. This material versatility is not just limited to the choice of material; it also extends to the ability to blend different materials to create composites with unique properties, expanding the possibilities for innovation and customization.