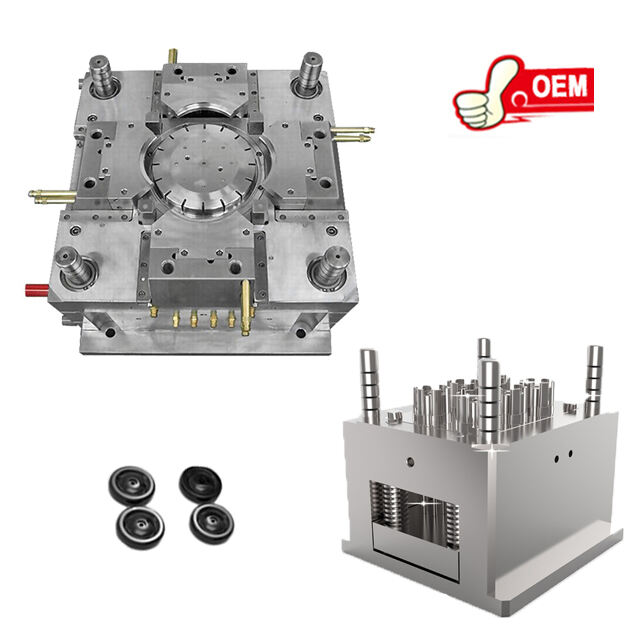

blow molding injection molding

Blow molding injection molding is a sophisticated manufacturing process that combines the precision of injection molding with the versatility of blow molding. Its main functions include producing hollow, seamless plastic products by injecting molten plastic into a mold and then blowing air into it to take its final shape. Technological features such as high-precision molds, automated controls, and rapid cycle times distinguish it, making it ideal for mass production. This process is used across various industries, from automotive and medical to packaging and consumer goods, providing a wide range of applications for manufacturers seeking durable and intricately shaped plastic products.