injection moulding business

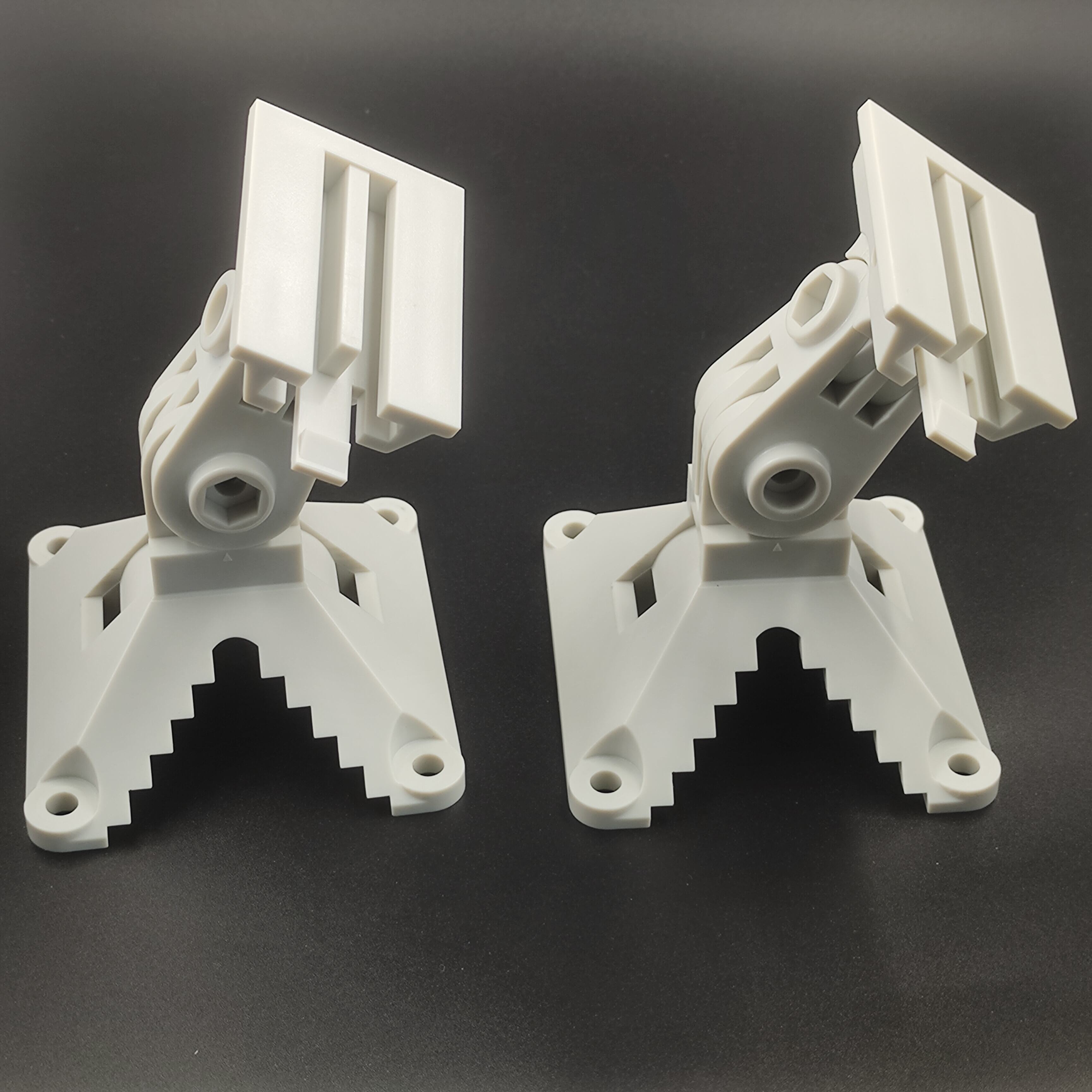

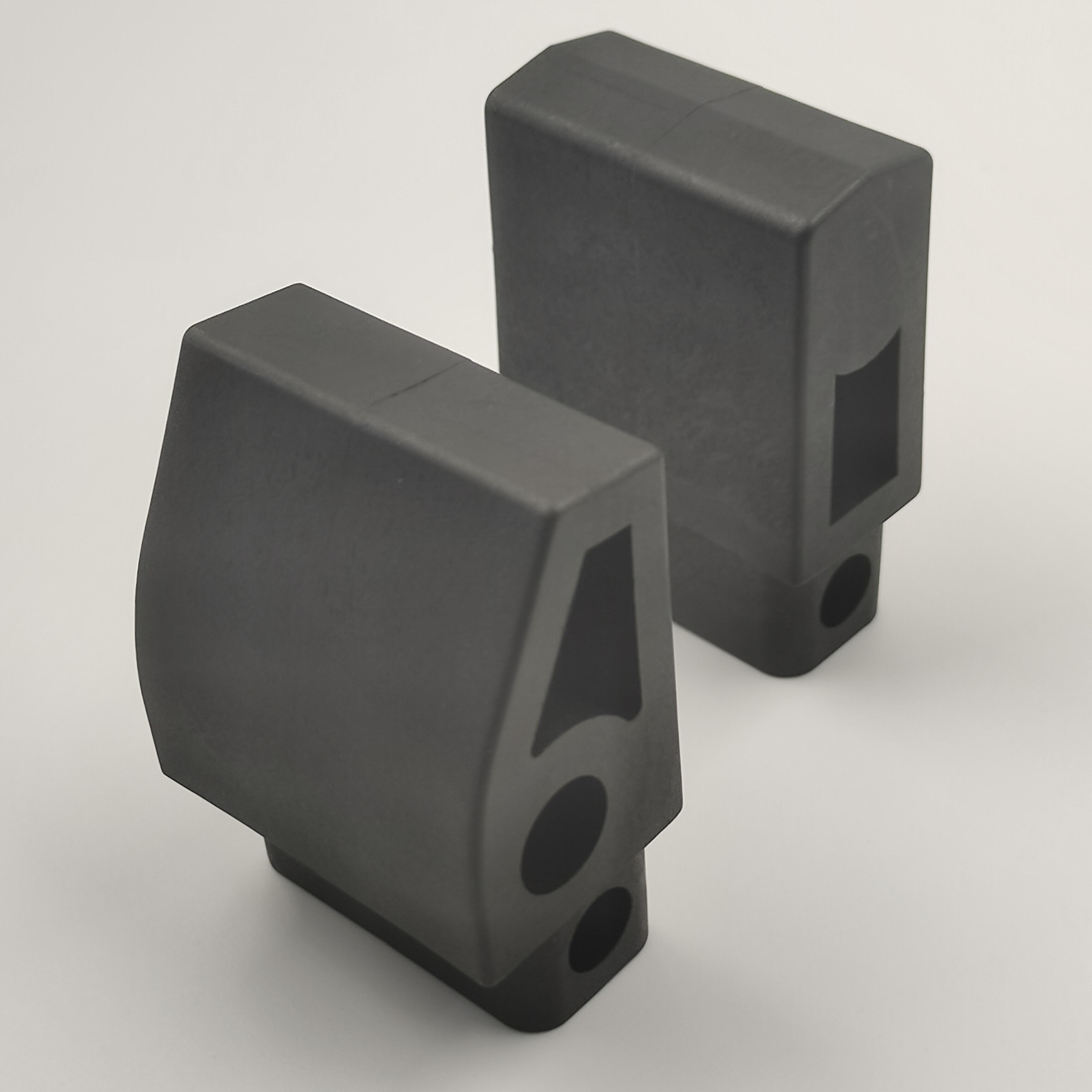

The injection moulding business is a cornerstone of modern manufacturing, specializing in the production of plastic parts and components through a sophisticated process that ensures precision and high volume output. At its core, injection moulding involves heating plastic material until it reaches a molten state, then injecting it into a mold cavity where it cools and solidifies to the desired shape. The main functions of this process include designing intricate molds, selecting the appropriate plastic material, and operating the machinery that facilitates the moulding. Technological features of injection moulding machines range from automated robotics that increase efficiency to advanced control systems that ensure product consistency. These capabilities make injection moulding ideal for a wide range of applications, from automotive parts and consumer goods to medical devices and electronic components.