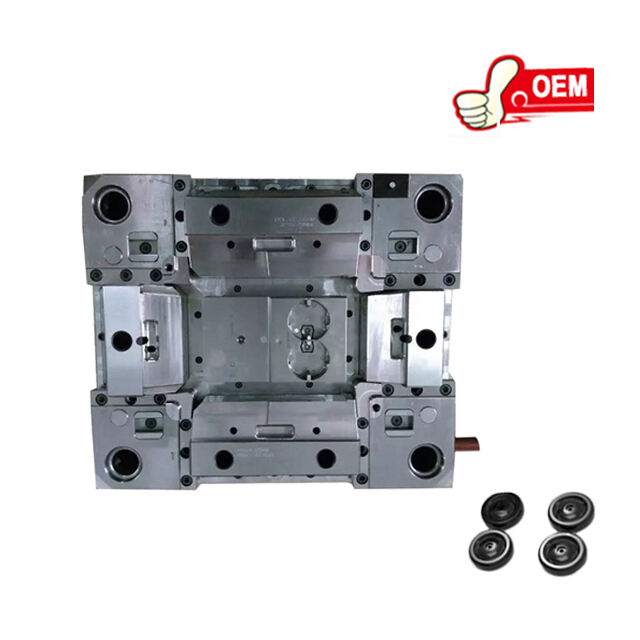

die plastic moulding

Die plastic moulding is a precision engineering process that involves shaping plastic materials using a custom-made die or mould. The main function of this process is to transform raw plastic materials into intricate and specific shapes that serve a wide range of industrial and consumer applications. Technological features of die plastic moulding include high precision, the ability to produce complex parts, and automation capabilities which enhance efficiency. The process typically involves heating the plastic until it is pliable, injecting it into a mould, then cooling it to set the final product. Applications range from automotive parts to medical devices, electronic components, and consumer goods, showcasing its versatility and importance in modern manufacturing.